Lynx

Table of contents

Introduction

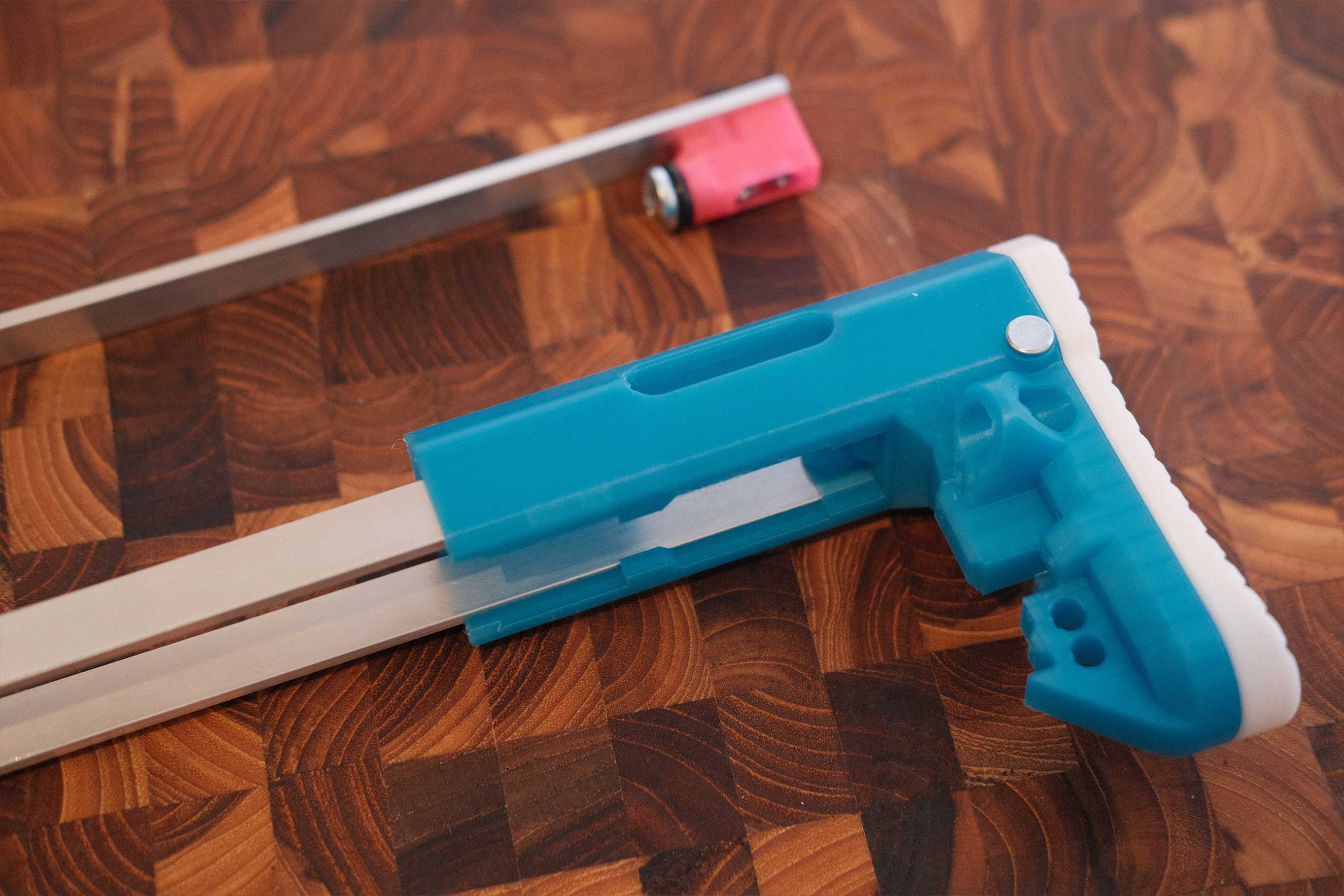

The Lynx is an open-source spring-powered blaster designed by Orion Blasters. CAD file and STL files are available here, and hardware kits are available here.

Features

(Pulled from the Orion Blasters’ Lynx page)

The Lynx is a Bullpup Mag-Fed Pump-Action Homemade Blaster for half length darts designed for the sport of Competitive Dart Tag. It features closed bolt mag swaps, slam-fire, is compatible with all longshot and talon claw springs, and can be completely disassembled without tools.

Lynx

Lynx

Lynx - Front Parts

Lynx - Front Parts

Lynx - Internals

Lynx - Internals

Lynx - Branding

Lynx - Branding

Lynx - Top View

Lynx - Top View

Build Guide

Plunger

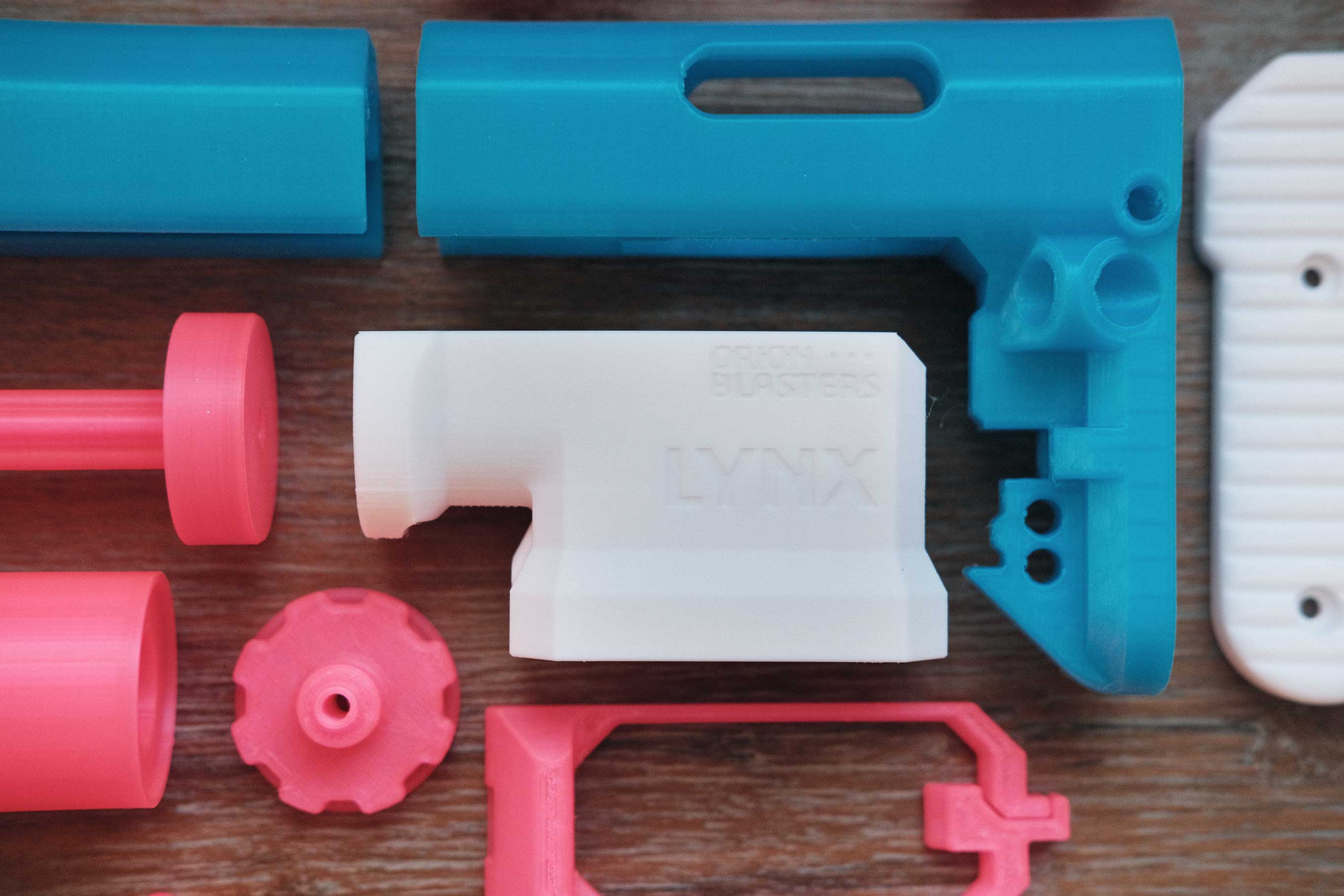

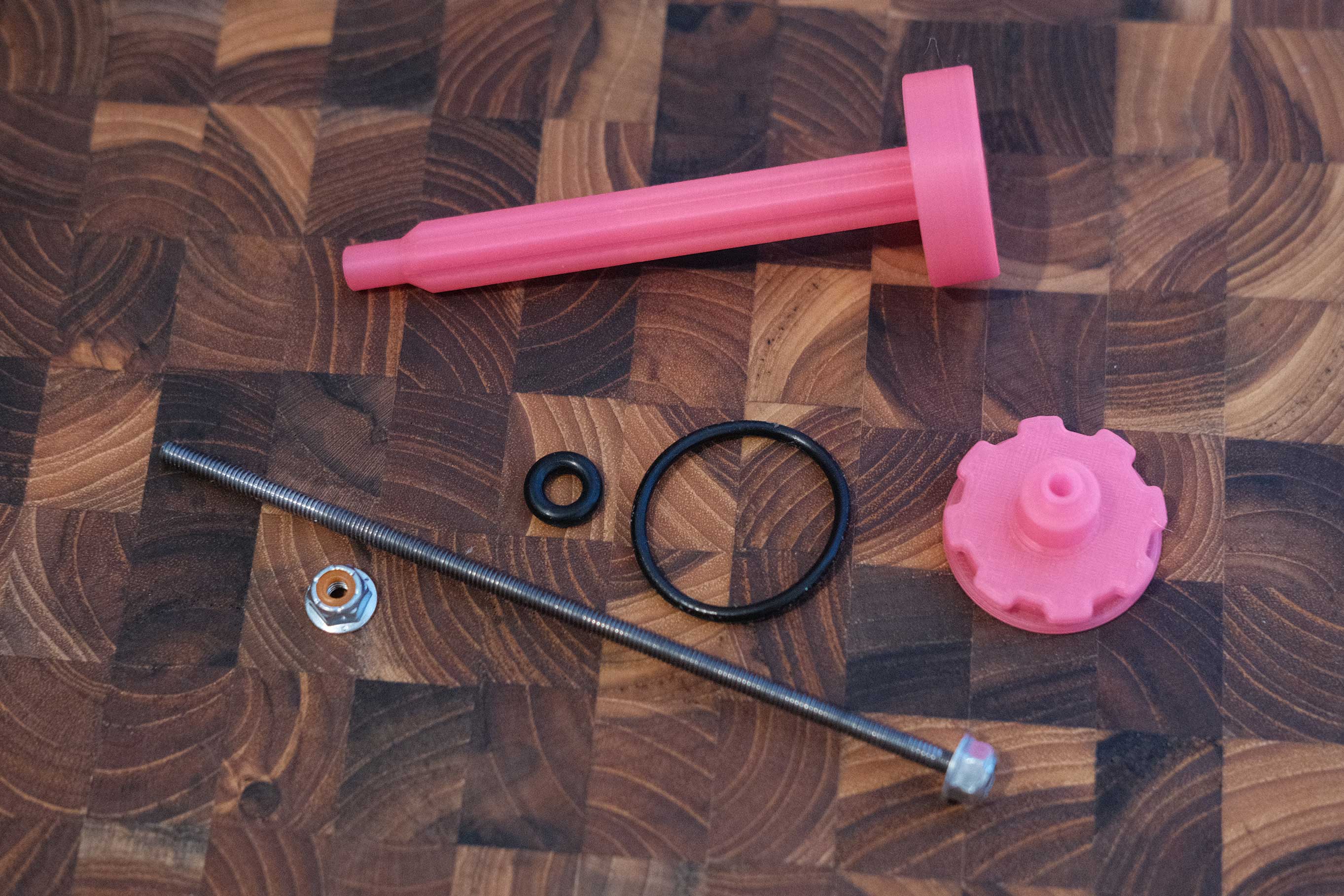

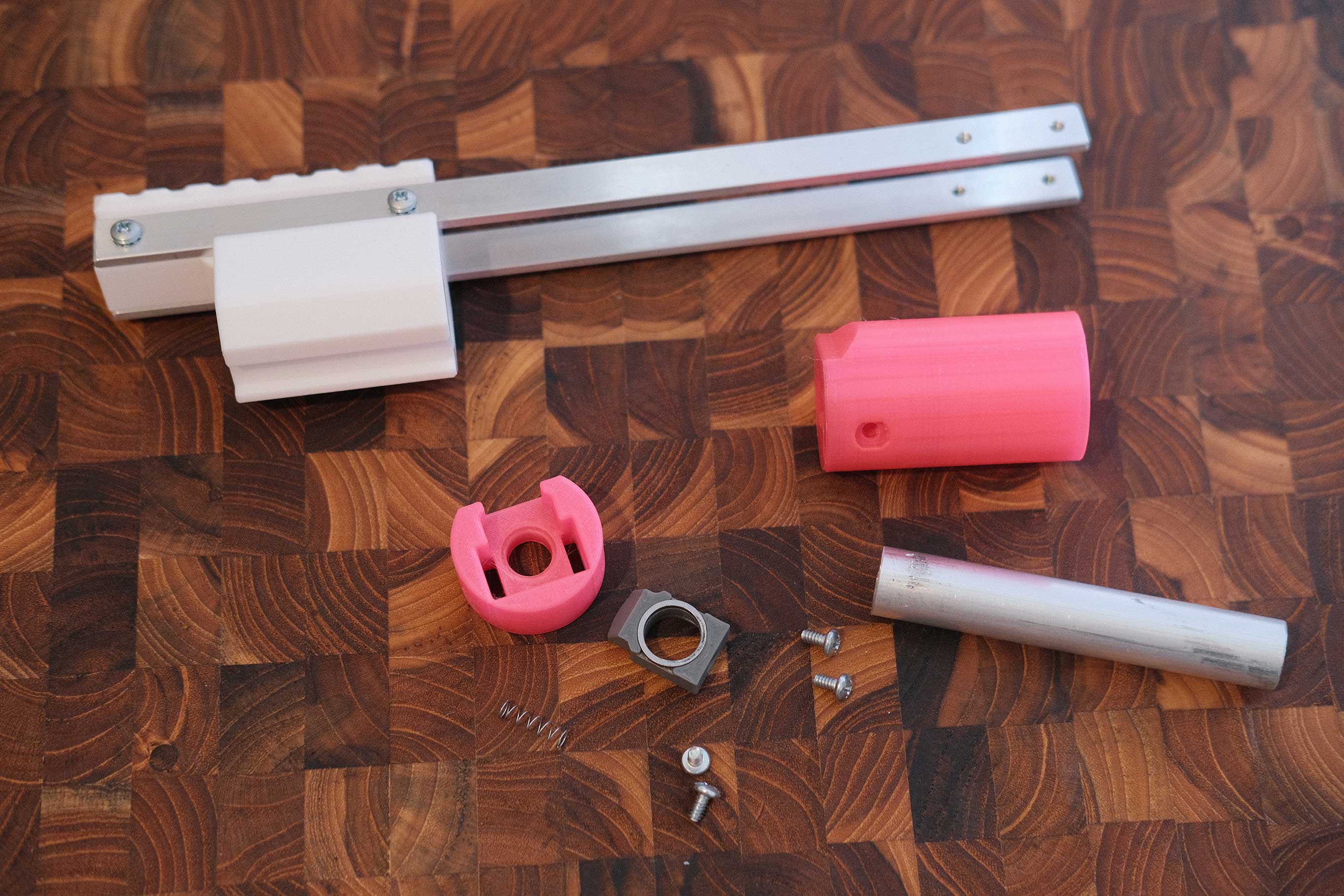

Plunger Parts

Plunger Parts

Plunger Assembled

Plunger Assembled

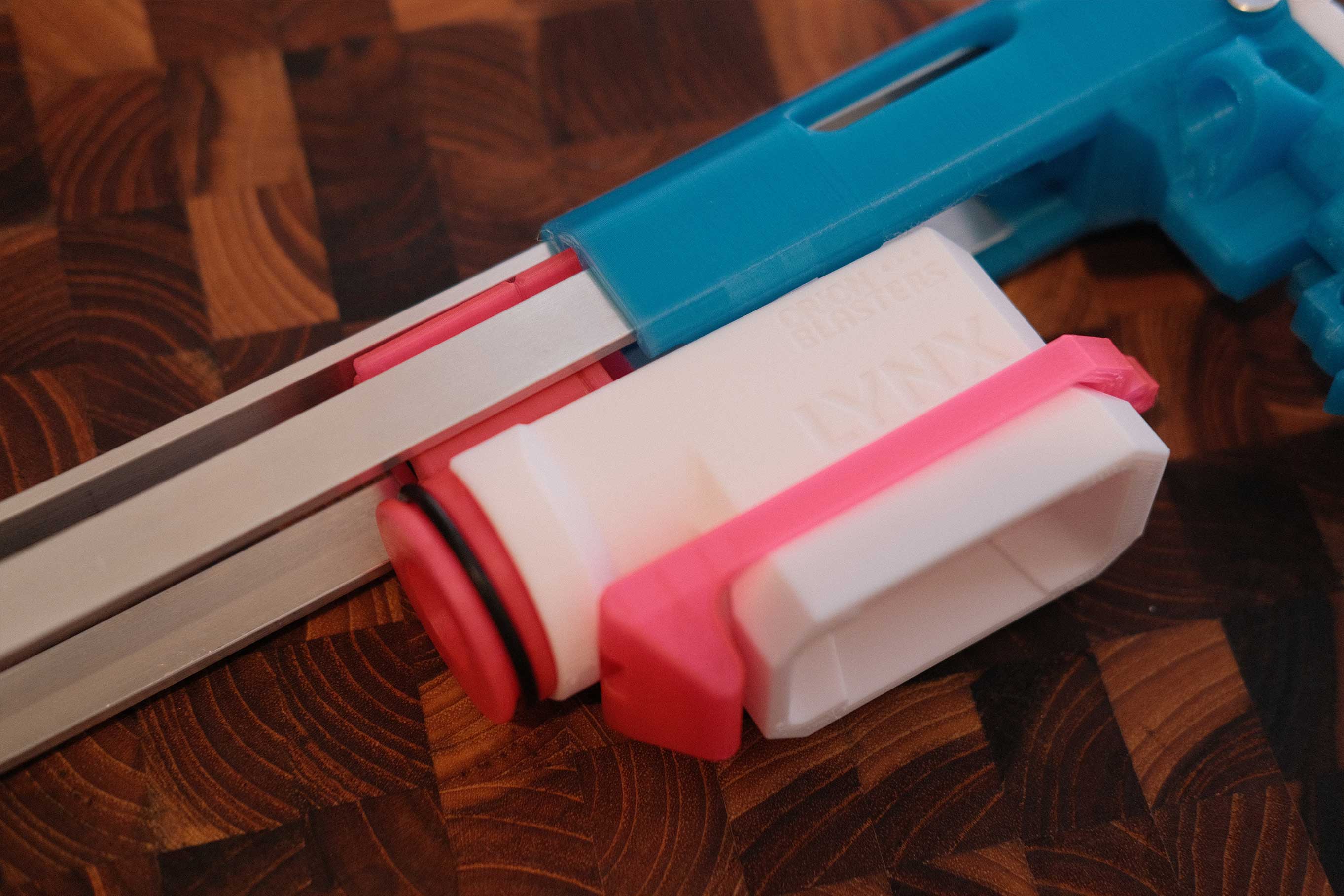

Test Fitment with Turnaround

Test Fitment with Turnaround

The o-ring nut controls how squished the o-ring is. You want it squished enough to get a good seal with the turnaround, but not so much that it’s hard to insert.

Test Fitment with Turnaround

Test Fitment with Turnaround

Stock

Stock Parts

Stock Parts

Stock Assembled

Stock Assembled

Magwell

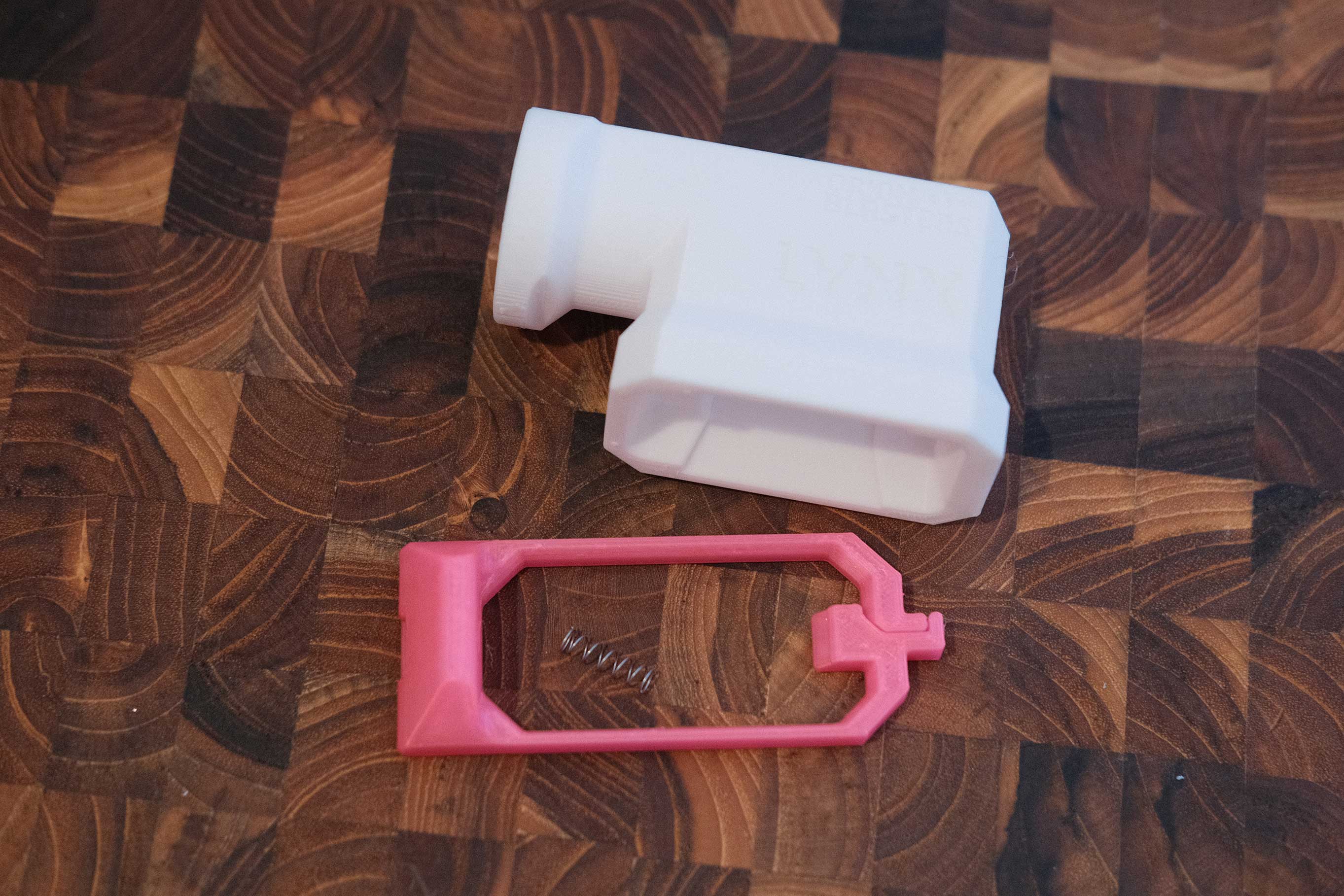

Magwell Parts

Magwell Parts

It’s a bit of a balancing act to get the spring seated while wrapping the release arms around the magwell, but it’s doable.

Magwell Assembled

Magwell Assembled

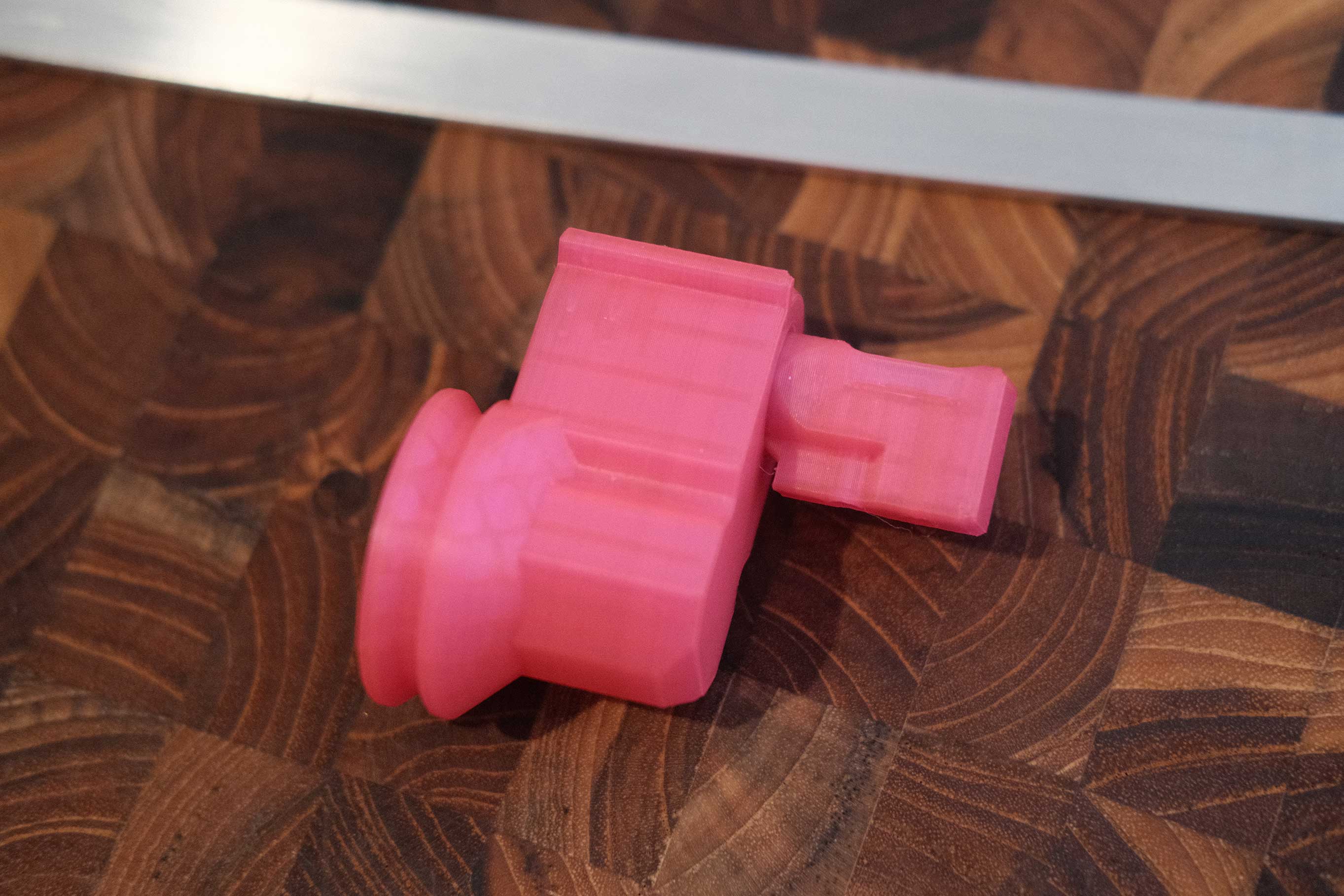

Ram Bar

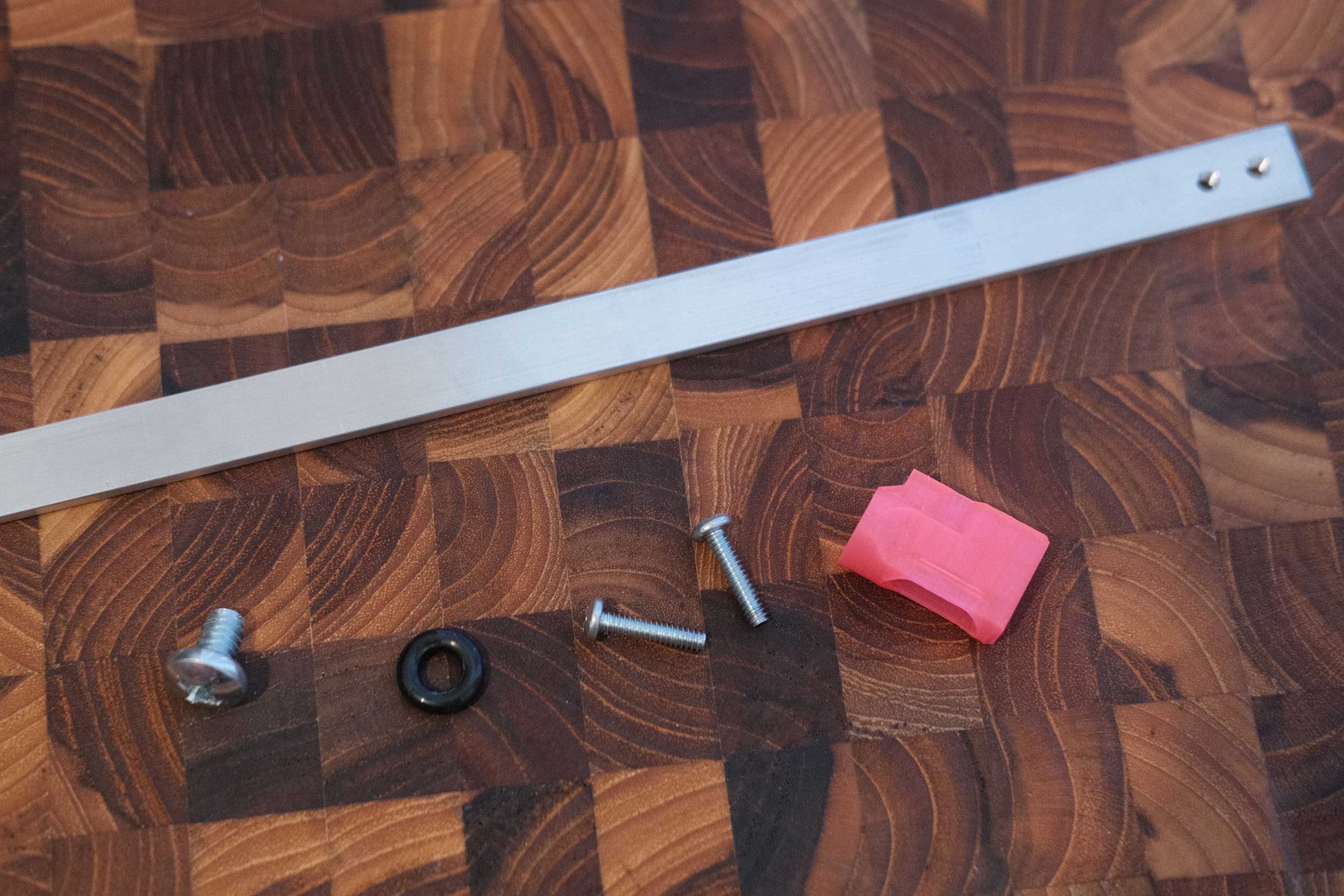

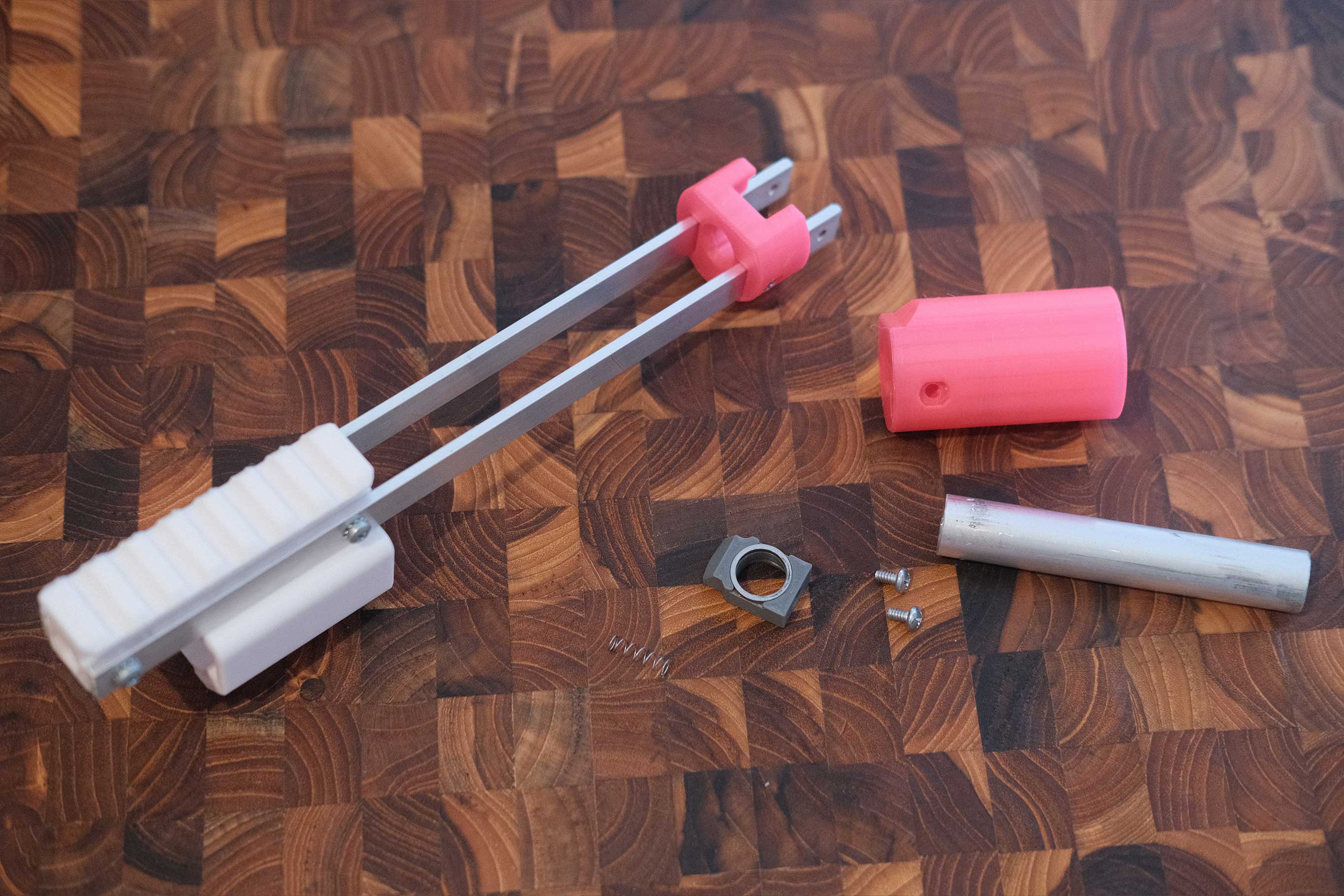

Ram Bar Parts

Ram Bar Parts

Take note of the orientation of the bar. The left cutout MUST be on the bottom.

Ram Bar Parts

Ram Bar Parts

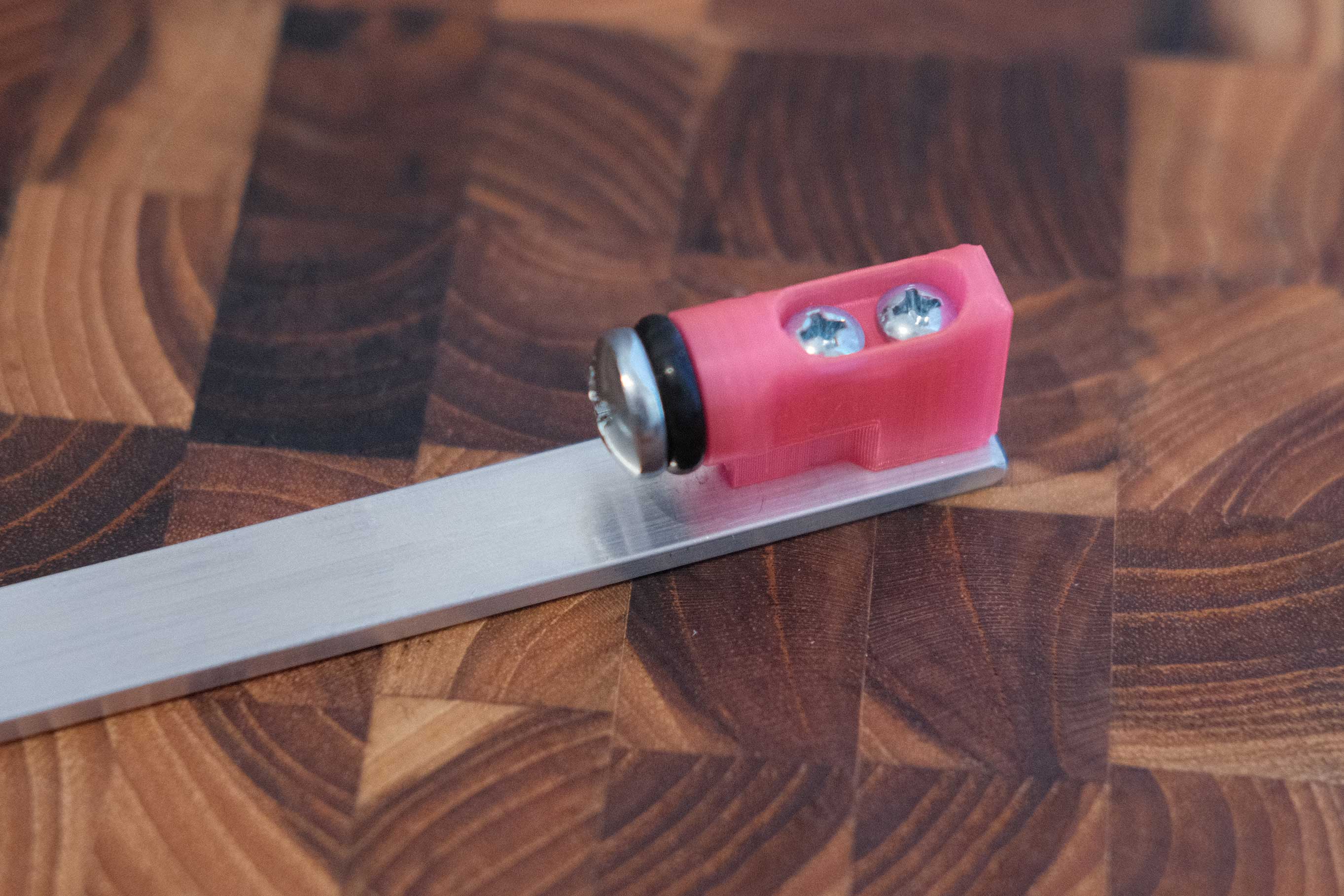

Test Fitment with Turnaround

Test Fitment with Turnaround

Similar to the plunger assembly, the ram has an o-ring that is adjusted by tightening the screw.

Test Fitment with Turnaround

Test Fitment with Turnaround

Ram Bar Assembled

Ram Bar Assembled

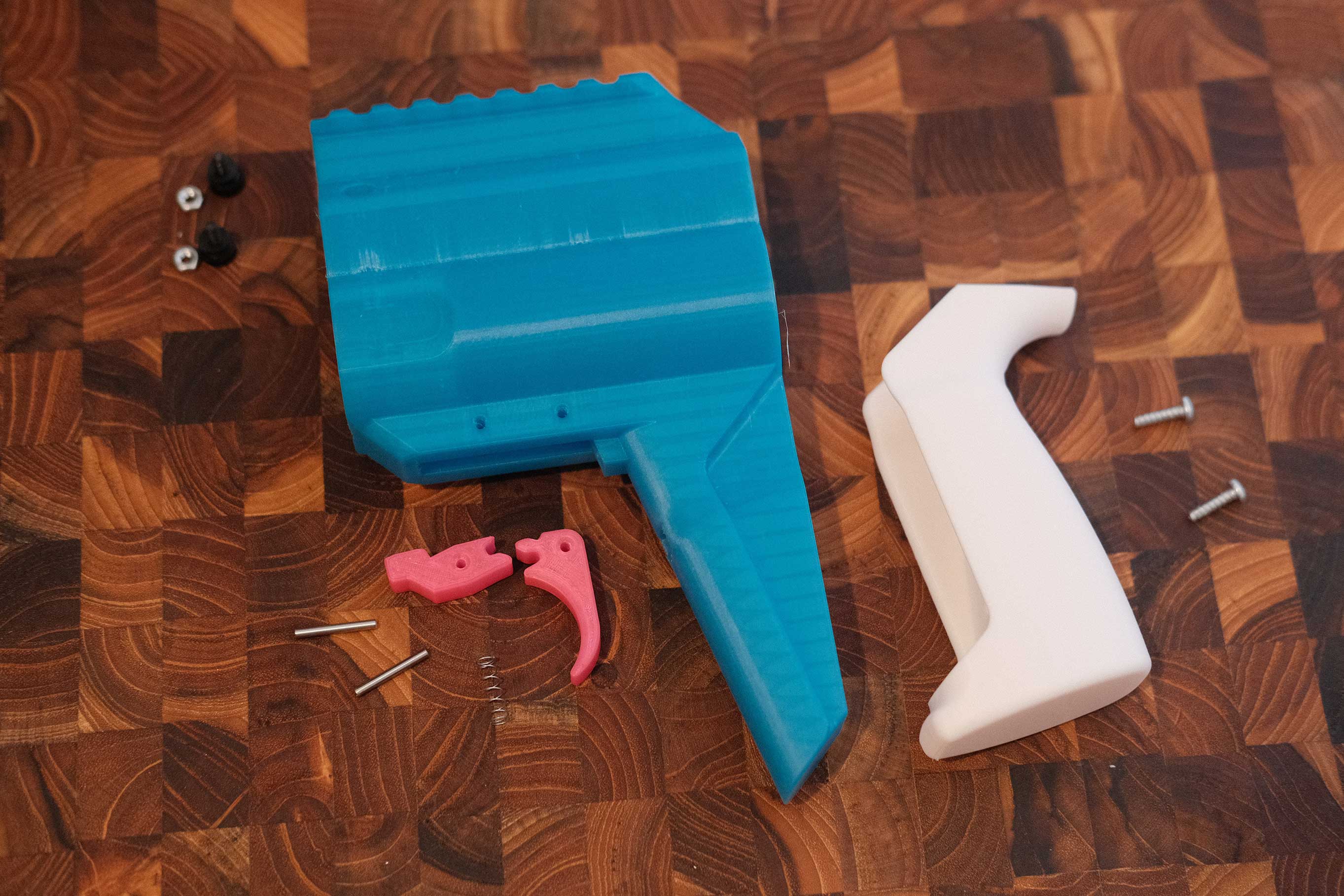

Receiver

Receiver Parts

Receiver Parts

Grip Installed

Grip Installed

Plastic Screws Installed

Plastic Screws Installed

The plastic screws and matching nuts go on top of the receiver and are responsible for holding the barrel in place. There are hex-shaped recesses inside the receiver to hold the nuts while the screws insert from the outside.

The trigger and sear are pinned in place with shafts. It helps to drill out the holes in plastic with a 3/32 drill bit for clearance.

Trigger and Sear Installed

Trigger and Sear Installed

Don’t forget the spring!

Test Trigger and Sear Action

Test Trigger and Sear Action

Check the trigger and sear action. When the trigger is not pulled, the sear should be flush.

Test Trigger and Sear Action

Test Trigger and Sear Action

When the trigger is pulled, the sear should rotate up.

Receiver Assembled

Receiver Assembled

The trigger guard flex-fits into place.

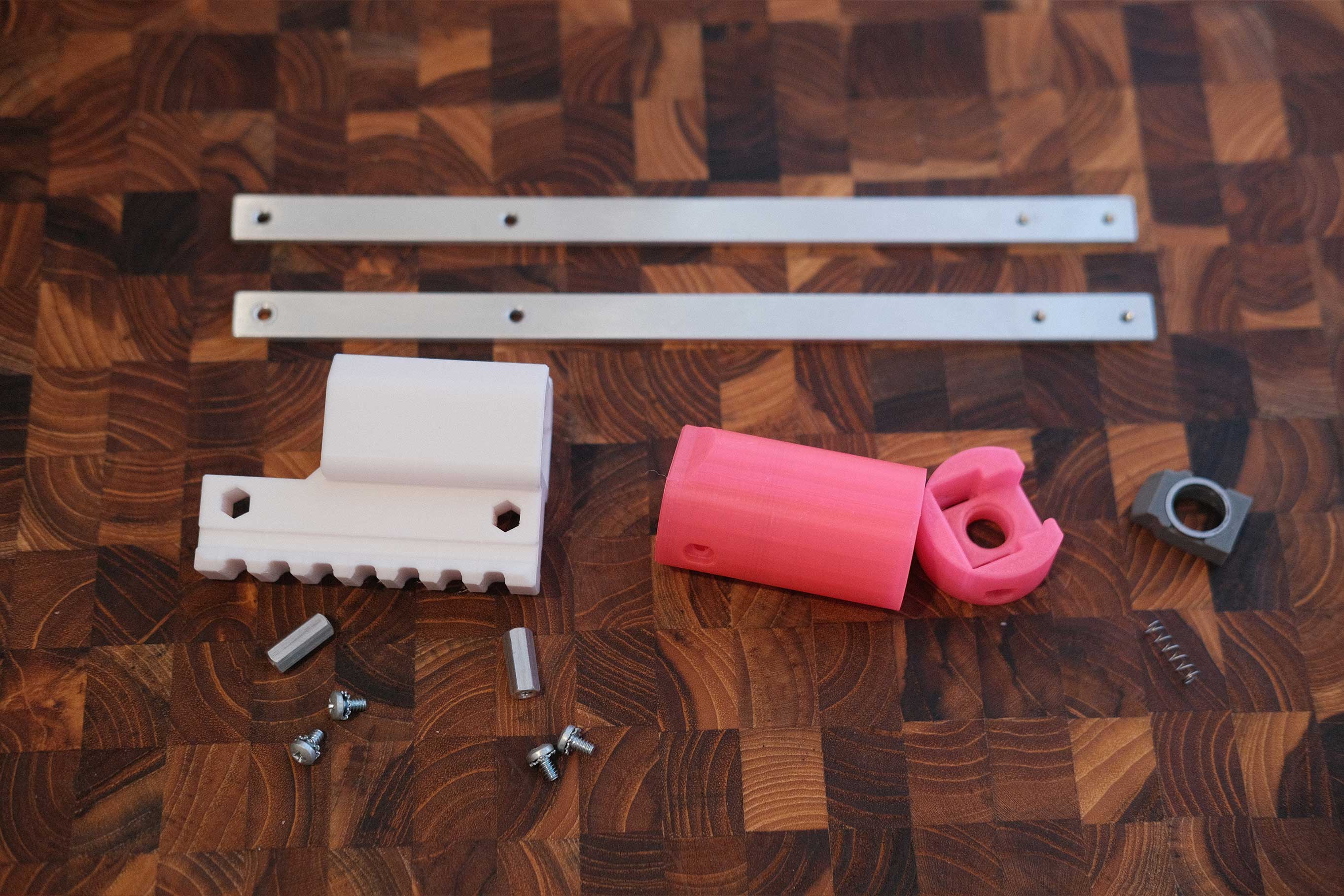

Pump Catch

Pump Catch Parts

Pump Catch Parts

Oops. Not shown are the 4 screws that secure the catch parts.

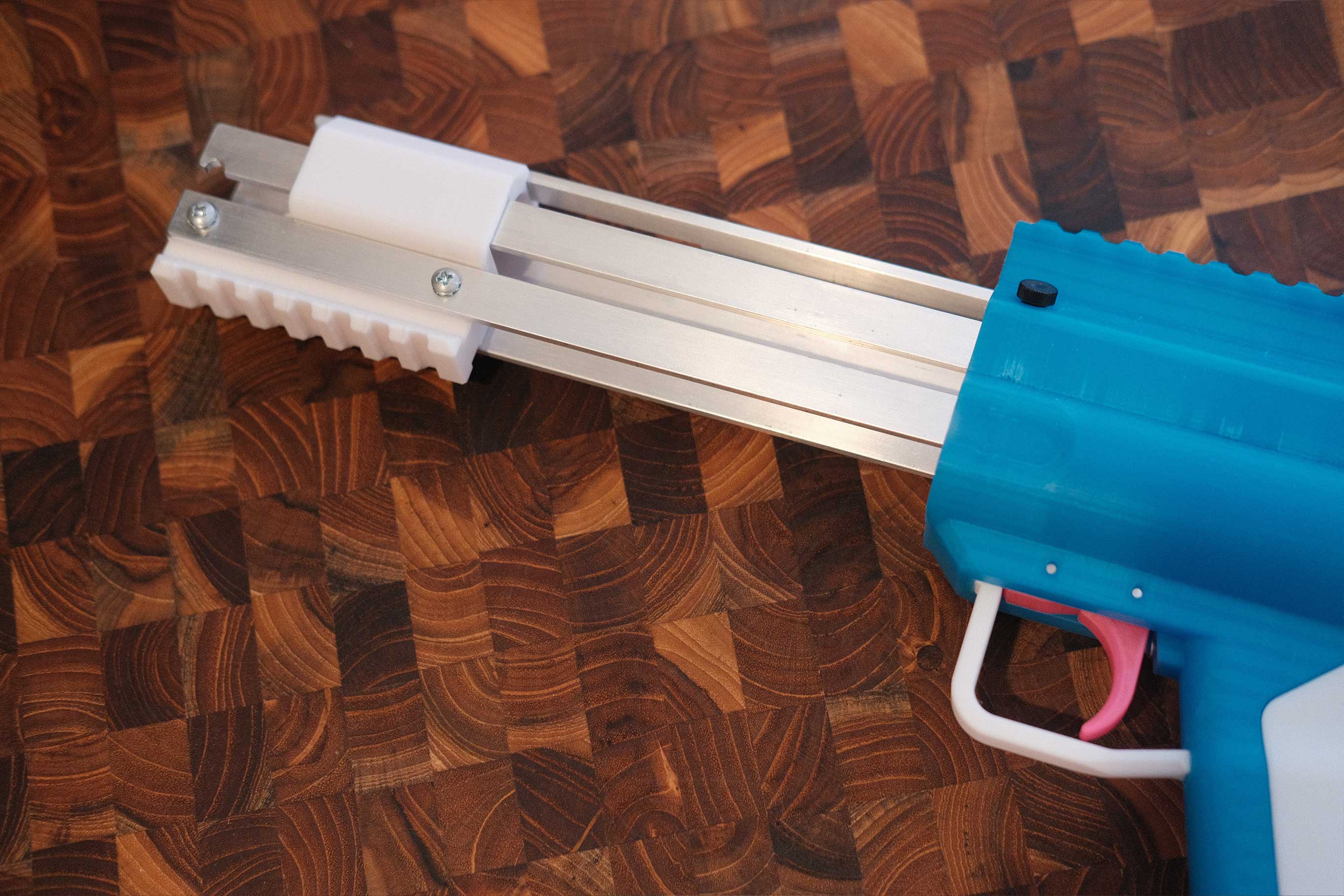

Pump Installed

Pump Installed

The 4 screws with toothed washers secure the pump to the front of the bars.

Smaller Catch Housing

Smaller Catch Housing

Secure the smaller catch housing first..

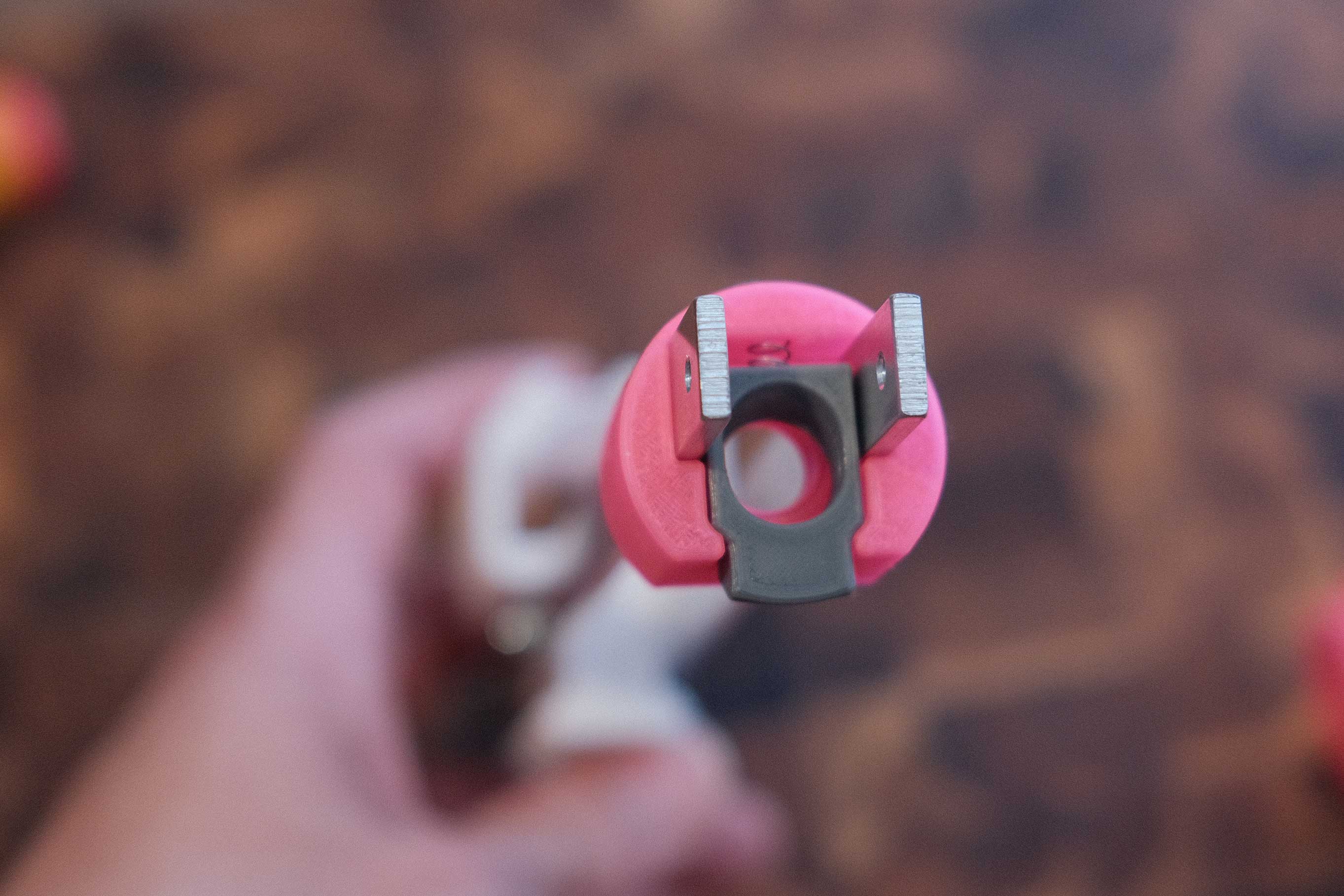

Catch and Spring

Catch and Spring

…then place the spring and reinforced catch like this. The flatter side of the catch should be facing towards the rear of the blaster.

Larger Catch Housing

Larger Catch Housing

Add the larger catch housing to trap the catch, insert the aluminum tube, and secure the tube with screws.

Test With Plunger

Test With Plunger

Test the catch with the plunger assembly.

Test With Plunger

Test With Plunger

Inserting the plunger should lock against the catch, and pressing on the catch should release the plunger.

Turnaround

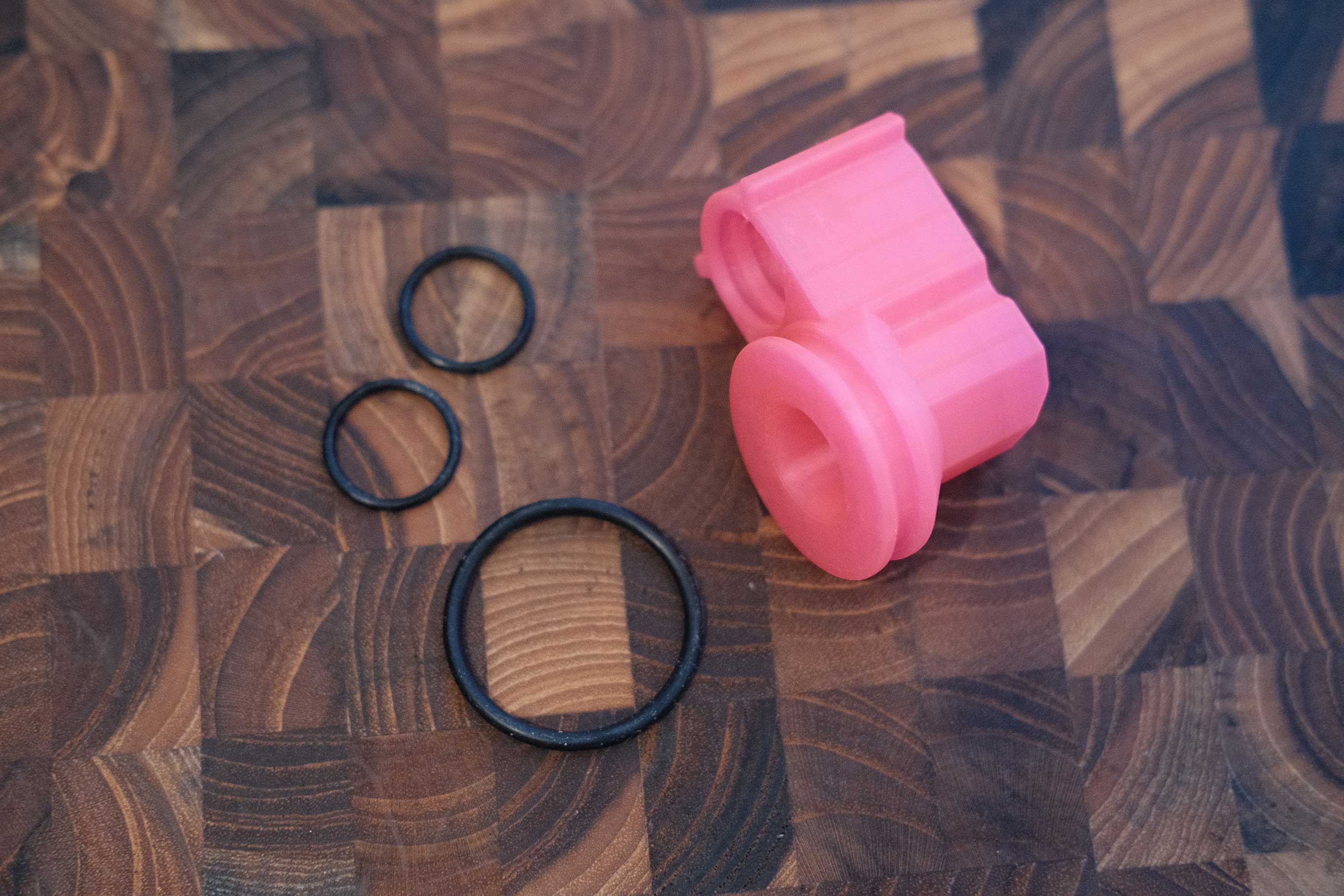

Turnaround Parts

Turnaround Parts

Turnaround

Turnaround

Final Assembly

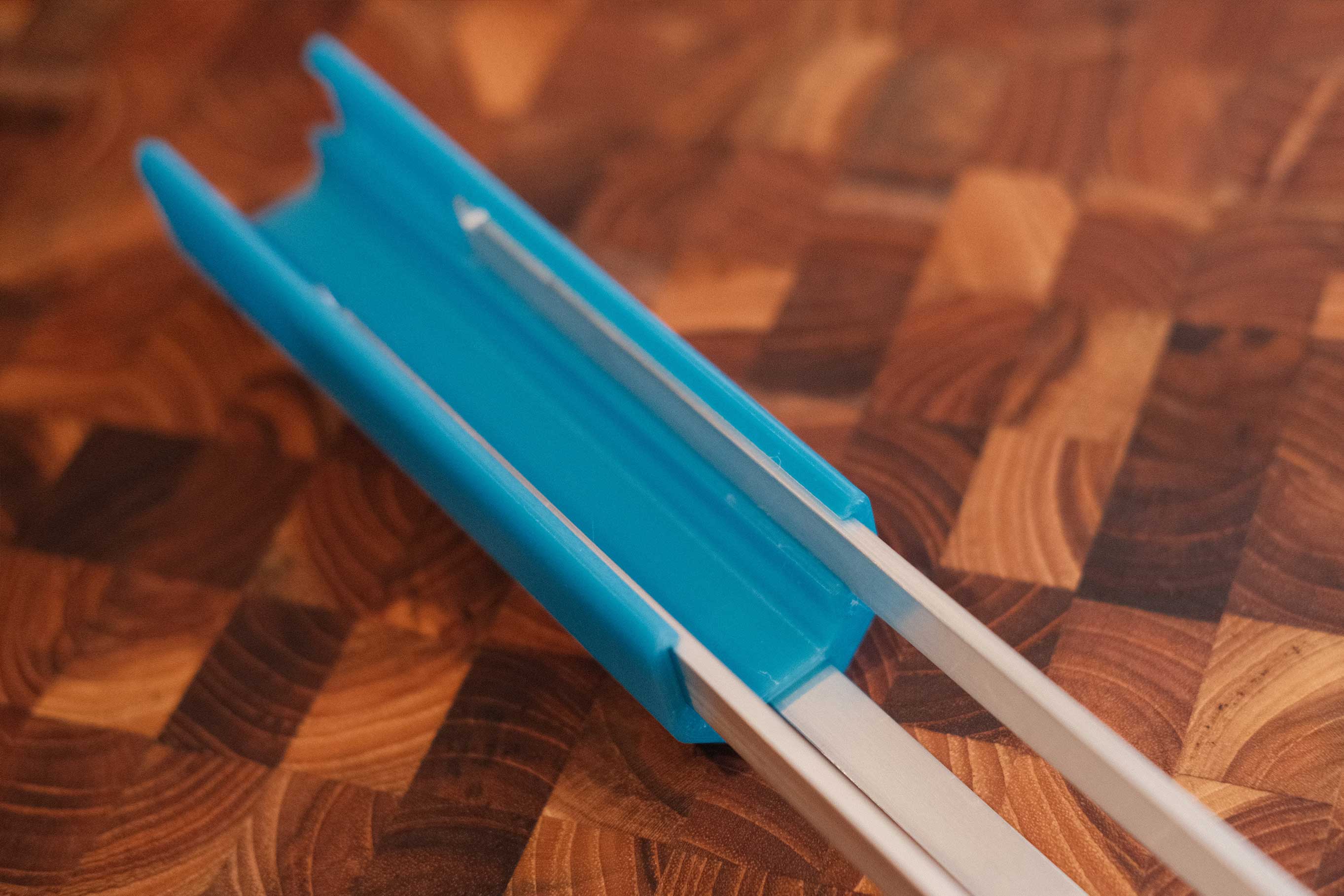

Stock and Side Bars

Stock and Side Bars

Stock and Side Bars

Stock and Side Bars

The bars sit in dedicated side channels, and have notches at the ends to lock in place with takedown pins.

Add Ram Assembly

Add Ram Assembly

Insert the ram assembly.

Add Ram Assembly

Add Ram Assembly

Add Ram Assembly

Add Ram Assembly

It should reach all the way to the back.

Add Magwell

Add Magwell

Add Magwell

Add Magwell

Add Magwell

Add Magwell

The little “ears” align with the 3 bars.

Add Magwell

Add Magwell

Magwell fits like so.

Add Spacer

Add Spacer

Add Spacer

Add Spacer

Slide the spacer on. There are dedicated channels for all 3 bars.

Add Plunger Tube

Add Plunger Tube

Add Plunger Tube

Add Plunger Tube

Twist the clear tube into place around the o-ring.

Add Receiver

Add Receiver

Add Receiver

Add Receiver

Slide on the receiver. There are dedicated channels for all 3 bars.

Add Thumb Release

Add Thumb Release

If you are using the optional thumb release, add it before sliding the receiver all the way.

Add Thumb Release

Add Thumb Release

Add Plunger and Spring

Add Plunger and Spring

Add some silicone grease around the oring to facilitate plunger action against the clear tube.

Add Plunger and Spring

Add Plunger and Spring

Add Ram Bar

Add Ram Bar

Add Ram Bar

Add Ram Bar

You will need lift up the ram bar to slide the pump assembly through. The pump fits in the notch in the ram bar.

Add Picatinny Rails

Add Picatinny Rails

Add Picatinny Rails

Add Picatinny Rails

Add Picatinny Rails

Add Picatinny Rails

Add Barrel

Add Barrel

Add Barrel

Add Barrel

You might need to loosen the top plastic screws to feed the barrel through. As the barrel bottoms out, it will push through the two o-rings inside the turnaround. Be careful that you don’t push them out of place. Retighten the top plastic screws to secure the barrel.

Complete

Complete

Your Lynx is complete!