Gryphon & Gryphle0n

Table of contents

Introduction

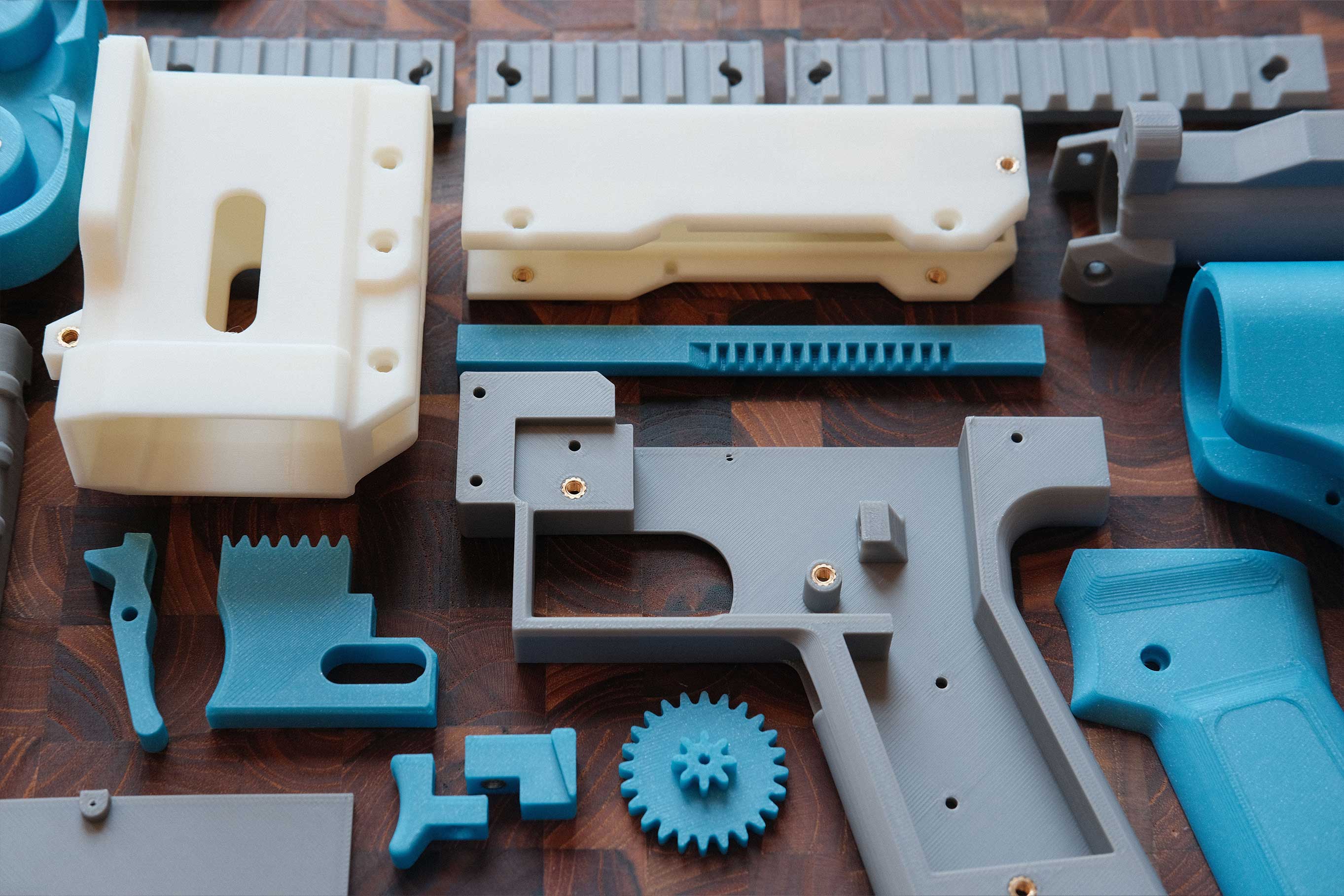

The Gryphon is an open-source flywheel blaster designed by Flygonial and available on Github. Most up to date CAD files can be found here.

Features

(Pulled from the Github page)

- Uses 130 to 180 sized 20.4mm , brushed DC motors.

- Semi-auto by rack and pinion with 1:3 gear multiplication. The trigger pull is fairly short at 12mm.

- Accepts 33 to 38mm OD flywheels (all 2mm shaft fit, superstock upgrade flywheels).

- Utilizes a horizontal flywheel cage that bolts directly onto the magwell. This is a mounting pattern less prone to misalignment than a Stryfe’s mounting bosses or similar.

- Accepts Worker Talon mags, Katana-geometry mags with a lower release cut-out, and almost all full-length magazines.

- Battery is located in the stock or a side battery tray.

- Full-length feed guide integrated in magwell for maximum feeding reliability.

- Bore-axis is almost as close as possible to top rail of blaster, which is theoretically more intuitive to aim with.

- Will fit on build volume as small as 120 mm3.

In my opinion, the Gryphon platform is solid, easy to print, relatively easy to assemble, and offers a lot of modding and upgrade potential. The Gryphle0n is my slightly modified version where superfluous decorations have been removed, some parts tweaked for better printability, and utilizes heatset inserts anywhere screws go directly into plastic.

Gryphle0n & Gryphon

Gryphle0n & Gryphon

Gryphle0n Front

Gryphle0n Front

Gryphle0n Grip

Gryphle0n Grip

Gryphle0n Middle

Gryphle0n Middle

Gryphle0n Top

Gryphle0n Top

Build Guide

BOM

- 2 x 130/180 motors

- 33-38mm, 2mm shaft-fit flywheels

- 16-18AWG multi-strand hobby wire

- XT60/XT30 connectors (2 female, 1 male)

- Heatshrink

- 21A full-size microswitch

- 2 x 20mm steel pins

- 0.5mm coil thickness, 5mm diameter, 15mm compression spring

- 0.5mm coil thickness, 5mm diameter, 50mm compression spring

- 4 x M2x4 FHCS

- 8 x M3x6 SHCS

- 22 x M3x8 SHCS

- 2 x M3x10 SHCS

- 4 x M3x12 SHCS

- 1 x M3x16 SHCS

- 2 x M3x20 SHCS

- 4 x M3x25 SHCS

- 4 x M3 nuts (Gryphon) or 34 x M3 heatset inserts (Gryphle0n)

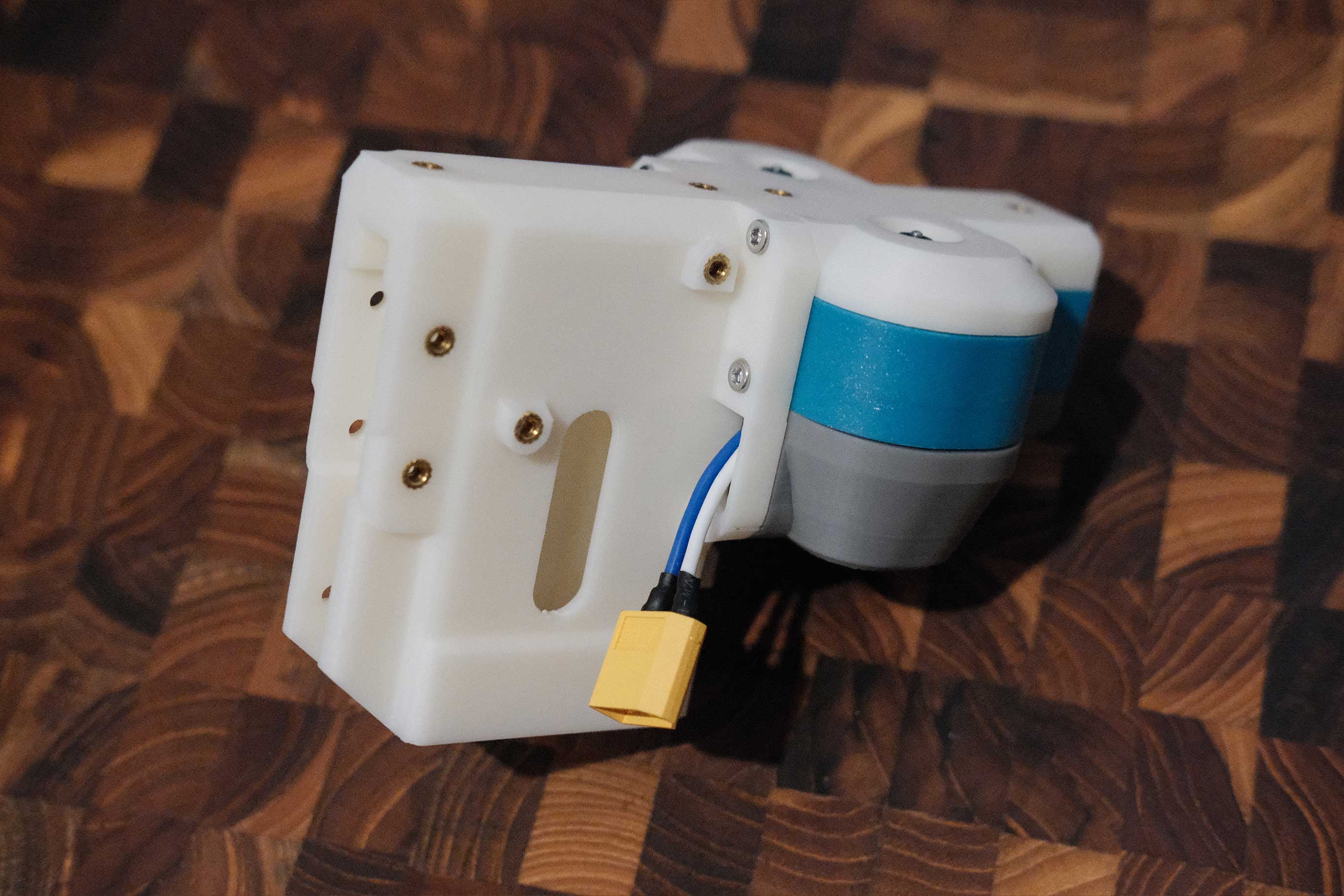

Cage

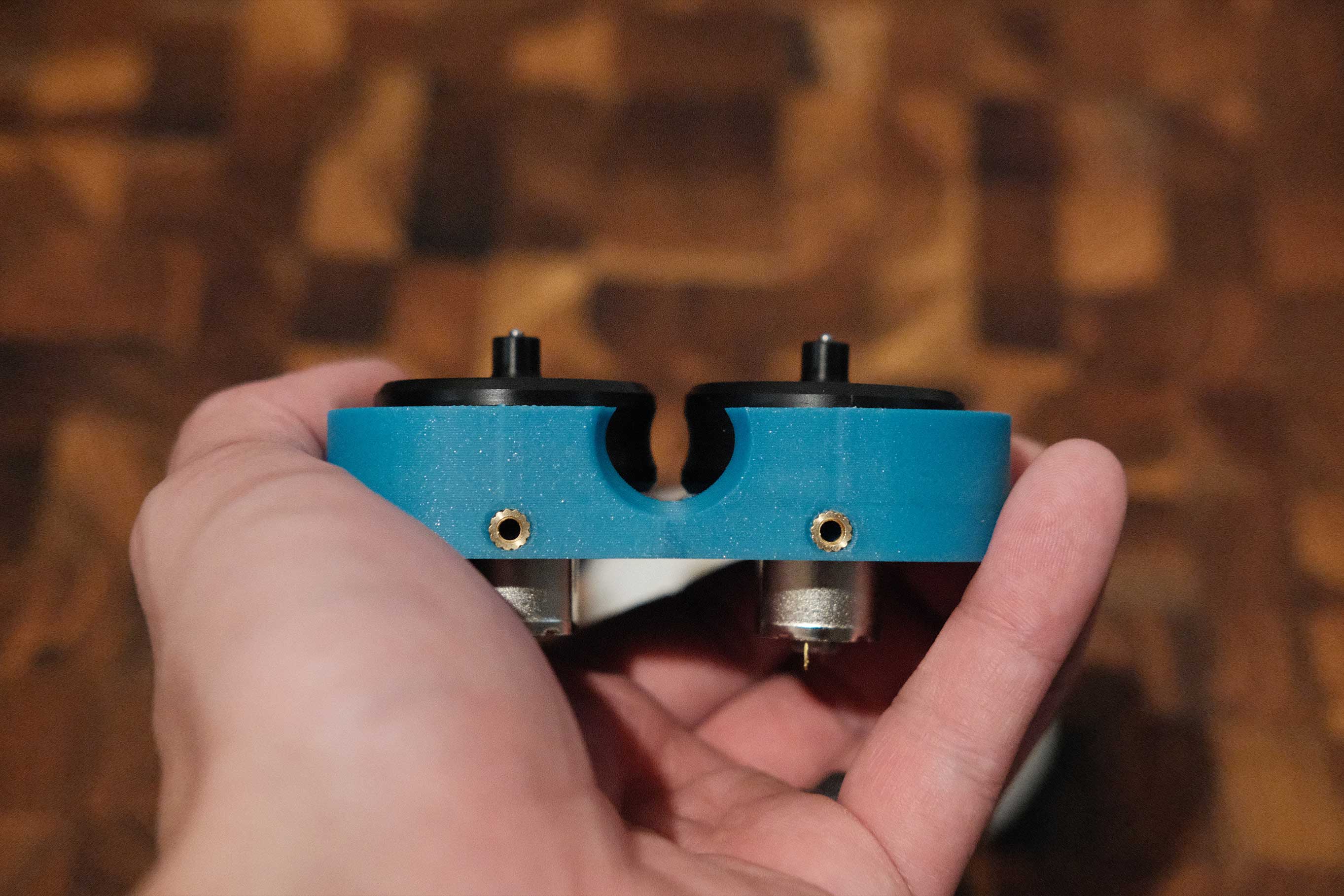

Mount Motors

Mount Motors

Double check the motors’ polarities, make sure the motors are fully seated, and that the shafts appear parallel to each other and perpendicular to the mounting.

- 4 x M2x4 FHCS

Mount Flywheels

Mount Flywheels

Check Flywheels’ Alignment

Check Flywheels’ Alignment

When press-fitting the flywheels, get them as even as possible with the flywheels’ middles centered to the dart hole. Additionally, check to make sure they aren’t binding and don’t rub against any plastic as they turn.

Install Flywheel Cover

Install Flywheel Cover

- 2 x M3x8 SHCS

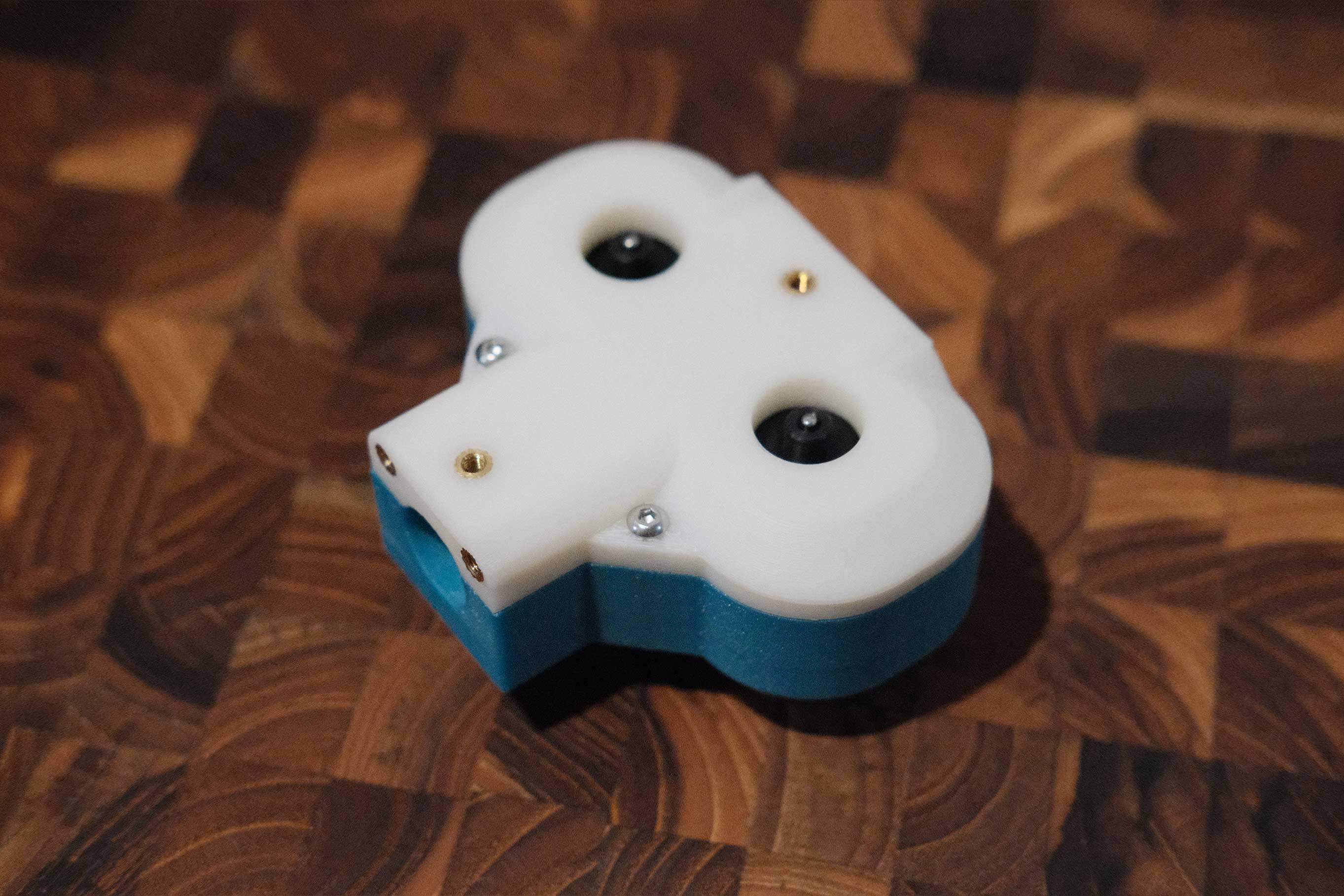

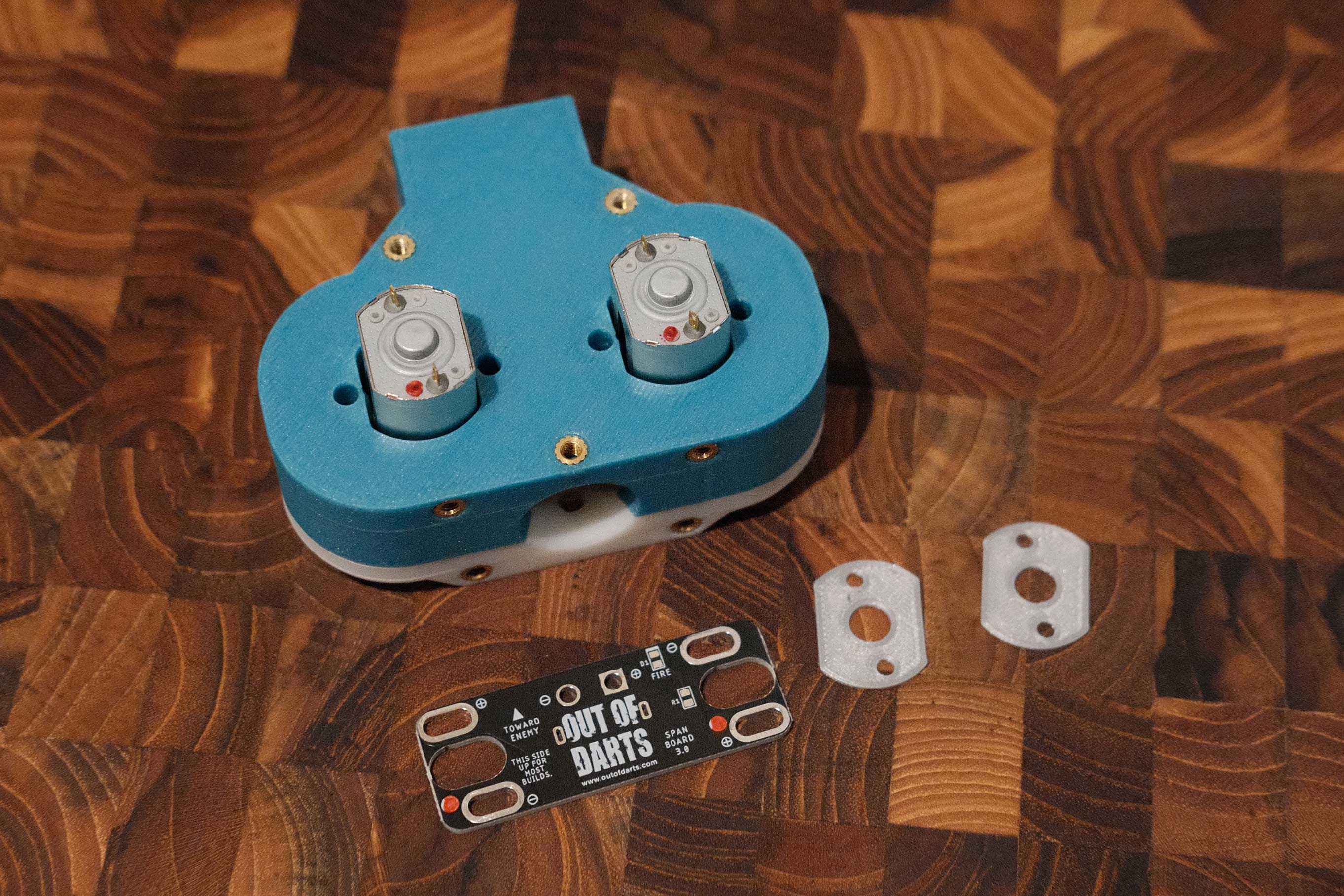

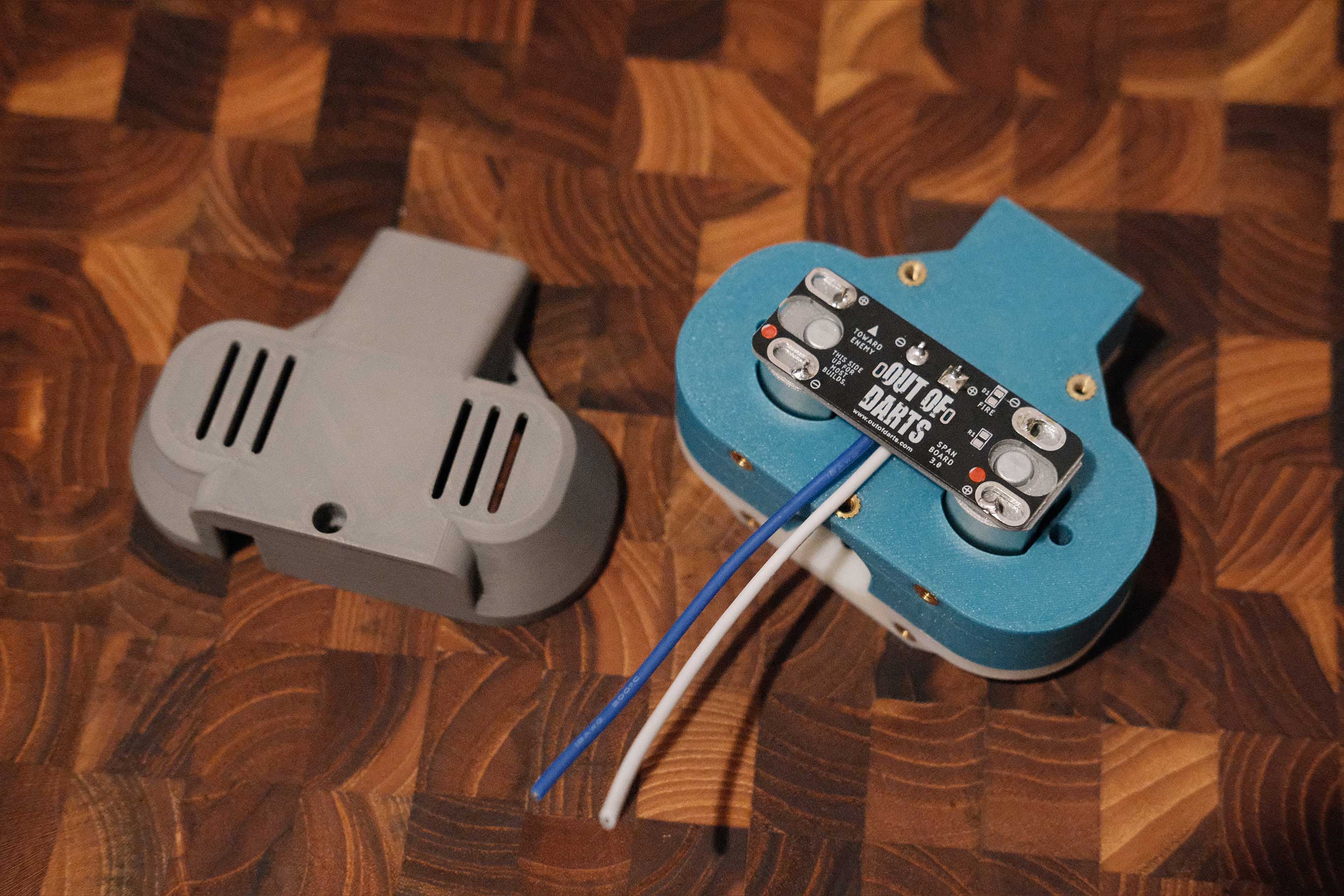

Out of Darts’ Motor Spanning Board

Out of Darts’ Motor Spanning Board

Out of Darts’ Motor Spanning Board makes wiring up the motors a bit easier. The PCB handles the inter-motor connections and you only have to deal with a pair of wires leading to the first XT60 female connector.

Place Motor Spacers

Place Motor Spacers

The motor spanning board comes with some printed spacers to give some clearance and prevent shorts. Place them like so.

Spanning Board Soldered

Spanning Board Soldered

Solder Wires for XT60 Connector

Solder Wires for XT60 Connector

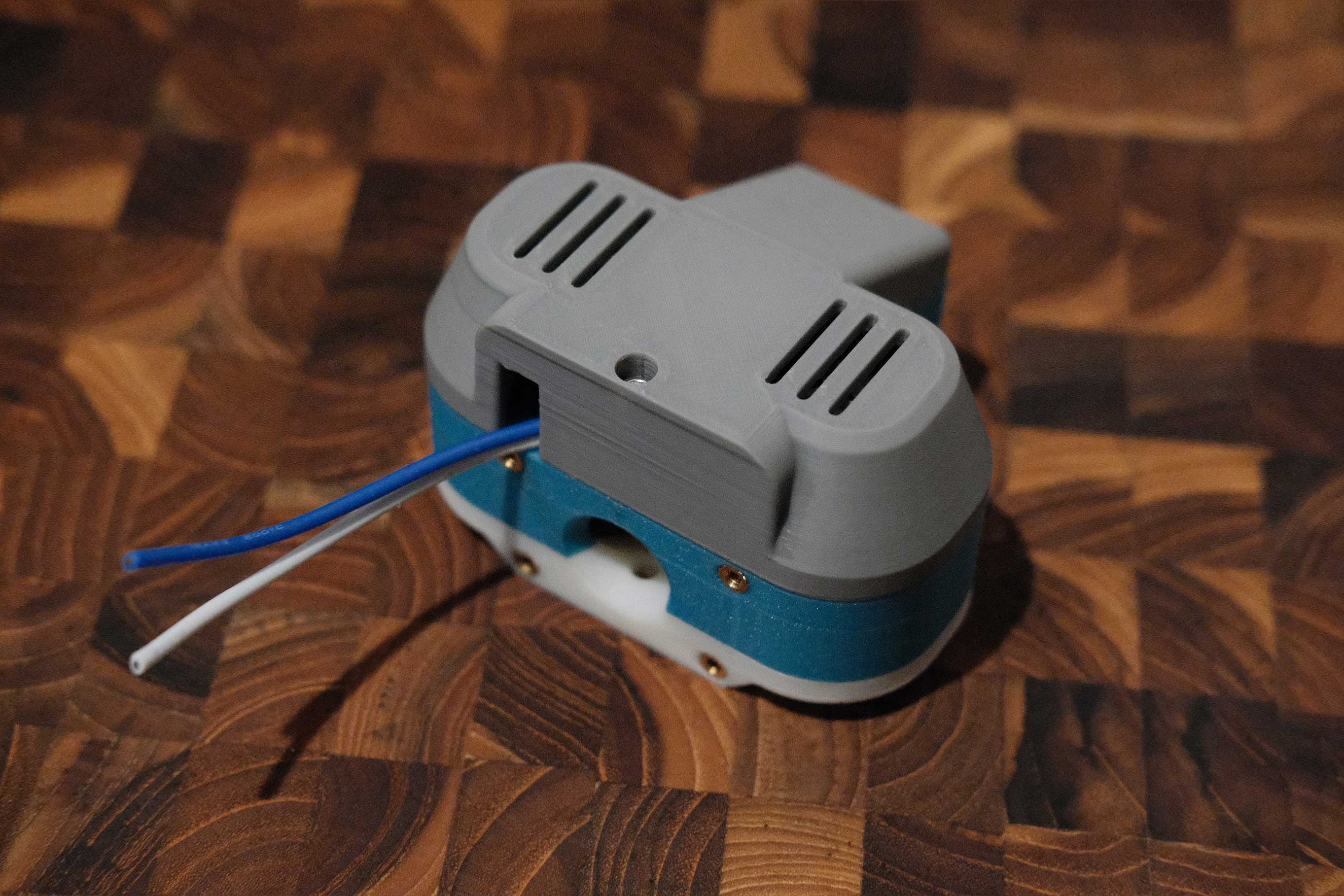

Install Motors’ Cover

Install Motors’ Cover

- 2 x M3x8 SHCS

- 1 x M3x20 SHCS

Check Wires Against Magwell for Length

Check Wires Against Magwell for Length

Feed the wires through the magwell to get a feel for the length required. The XT60 connector here will sit underneath a wire cover.

Solder and Heatshrink the XT60 Female Connector

Solder and Heatshrink the XT60 Female Connector

Don’t forget to place the heatsinks on the wires before soldering to the XT60 female connector. In this particularly case, the motors were oriented per the PCB’s markings, but still ended spinning the wrong way, so I inverted the XT60 to correct it.

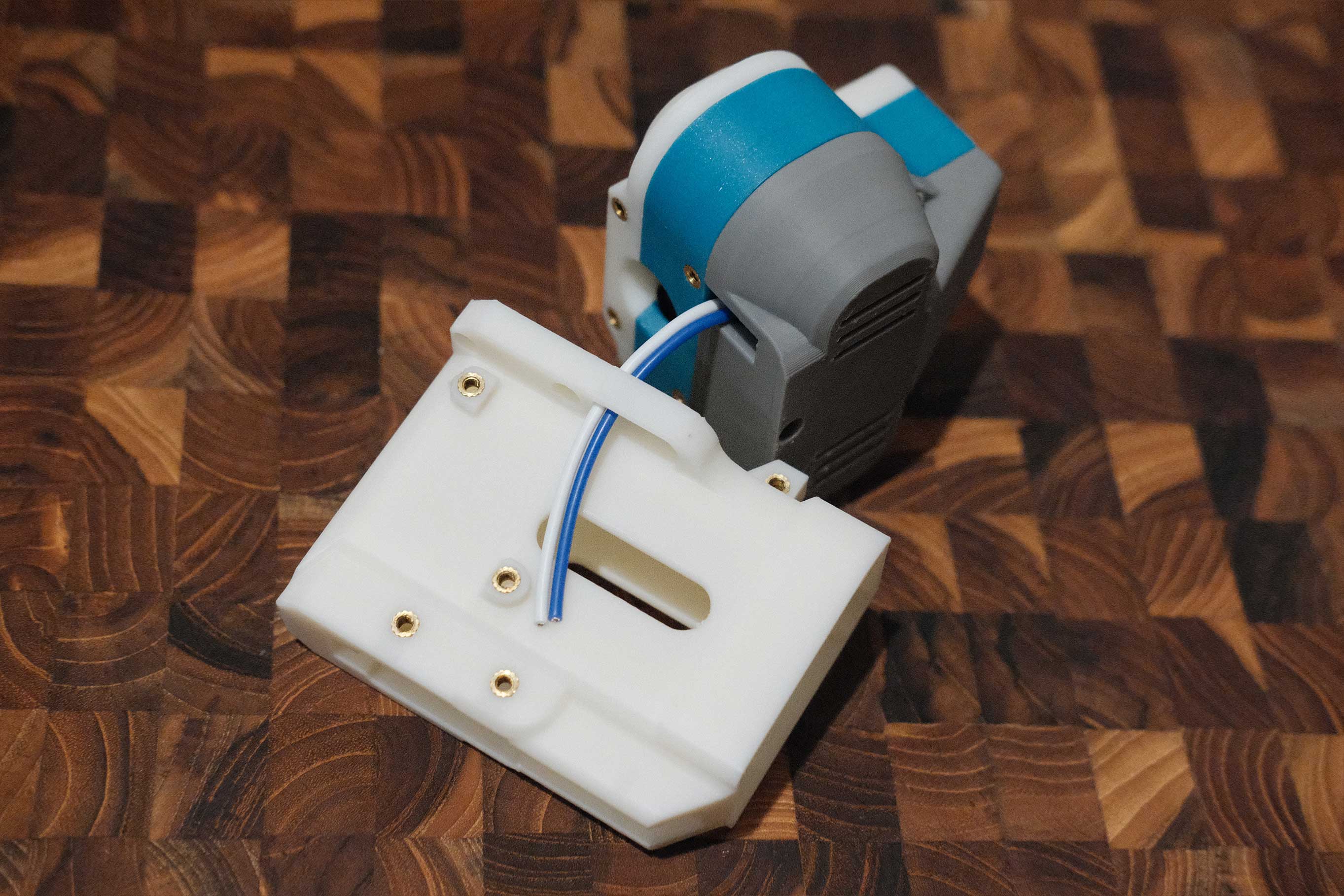

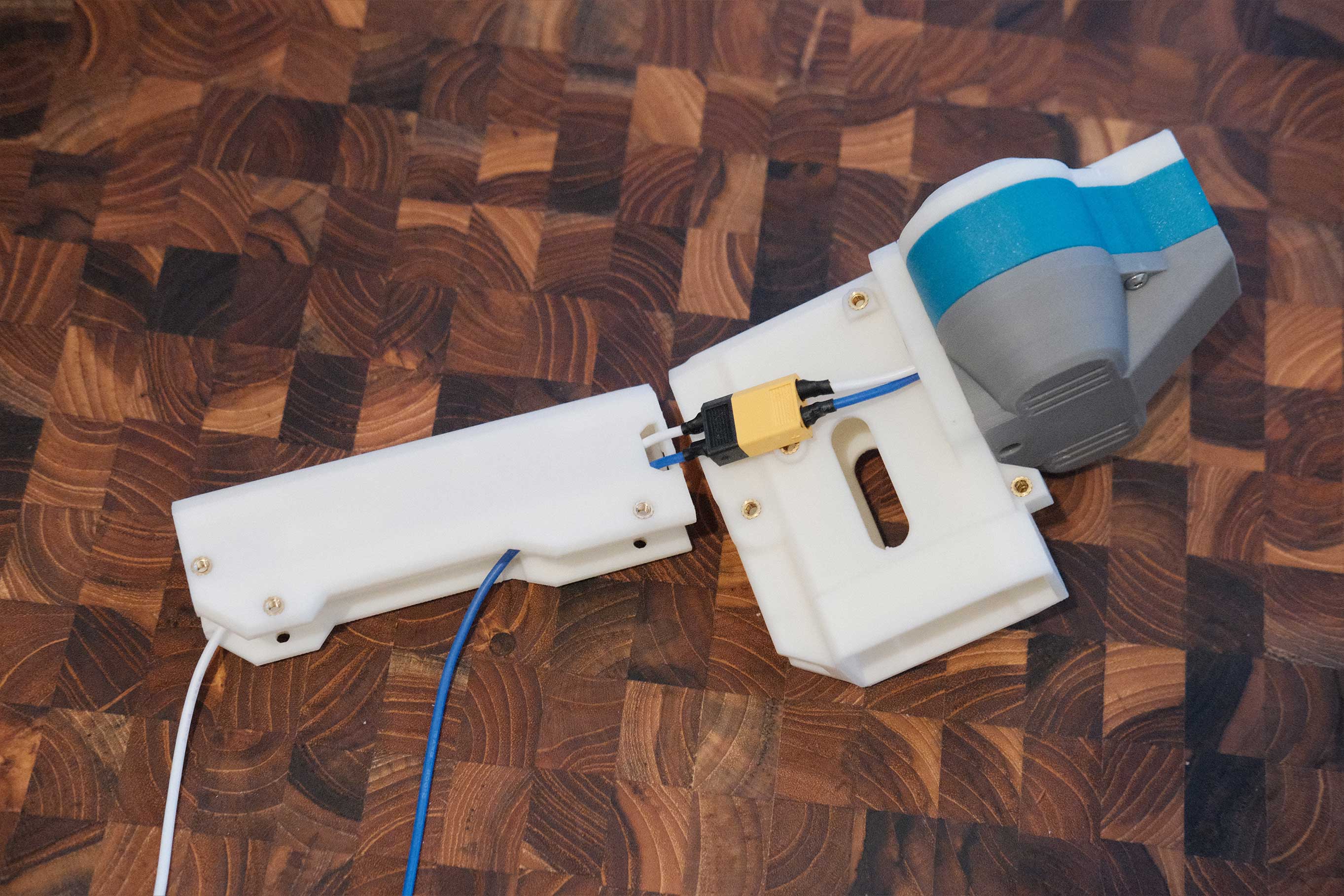

Magwell

Attaching Magwell

Attaching Magwell

- 4 x M3x8 SHCS

Magwell attached

Magwell attached

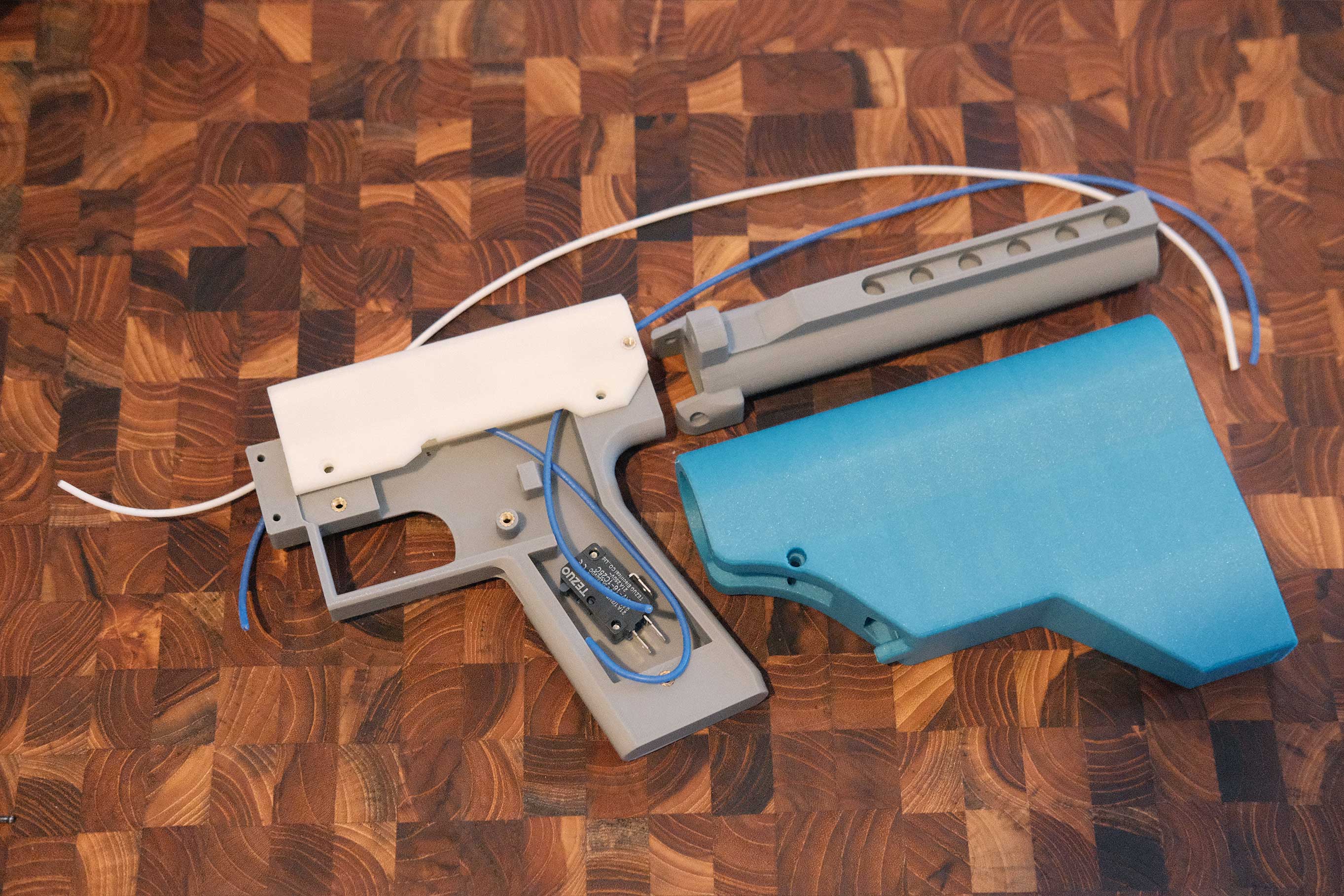

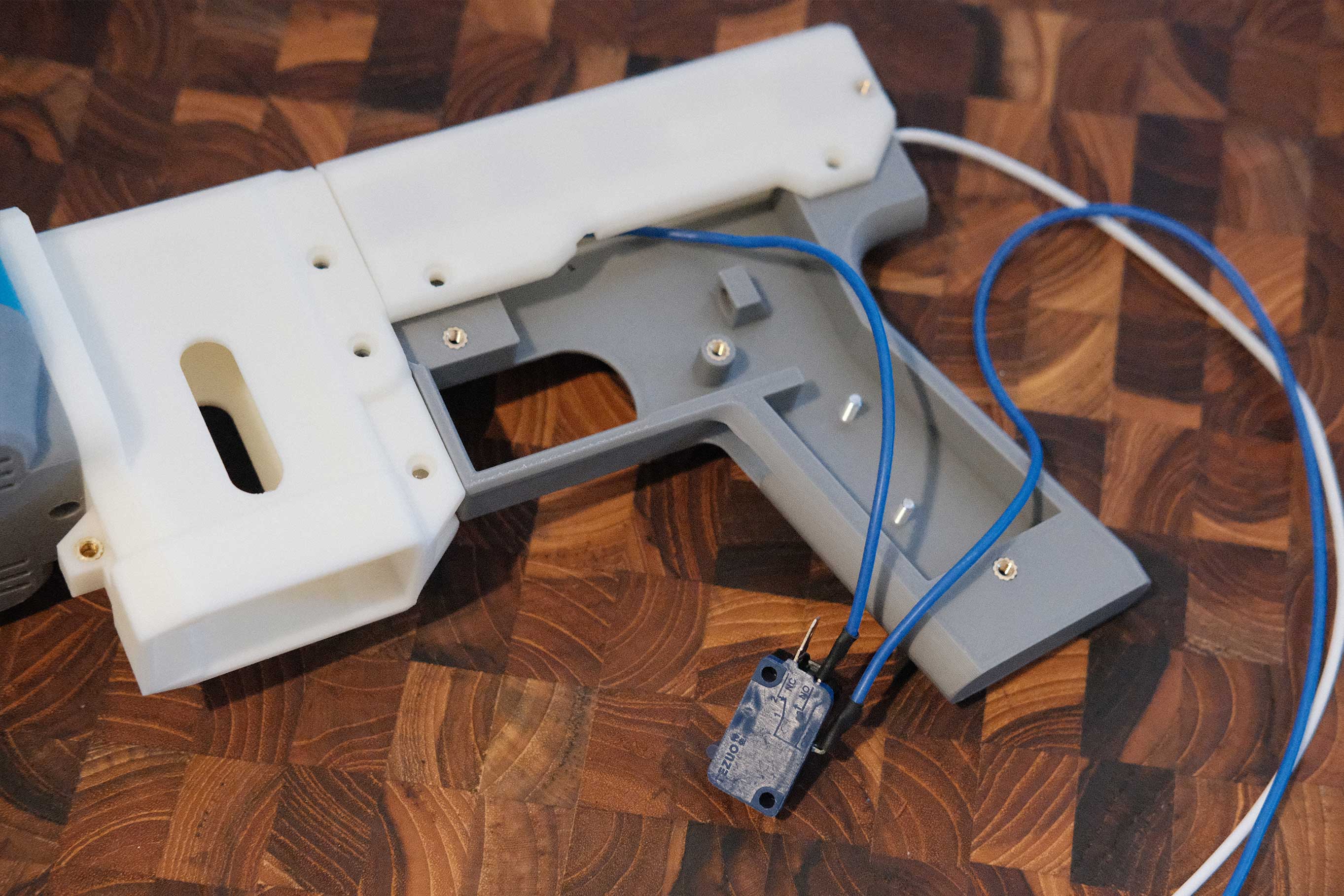

Grip

Grip

Grip

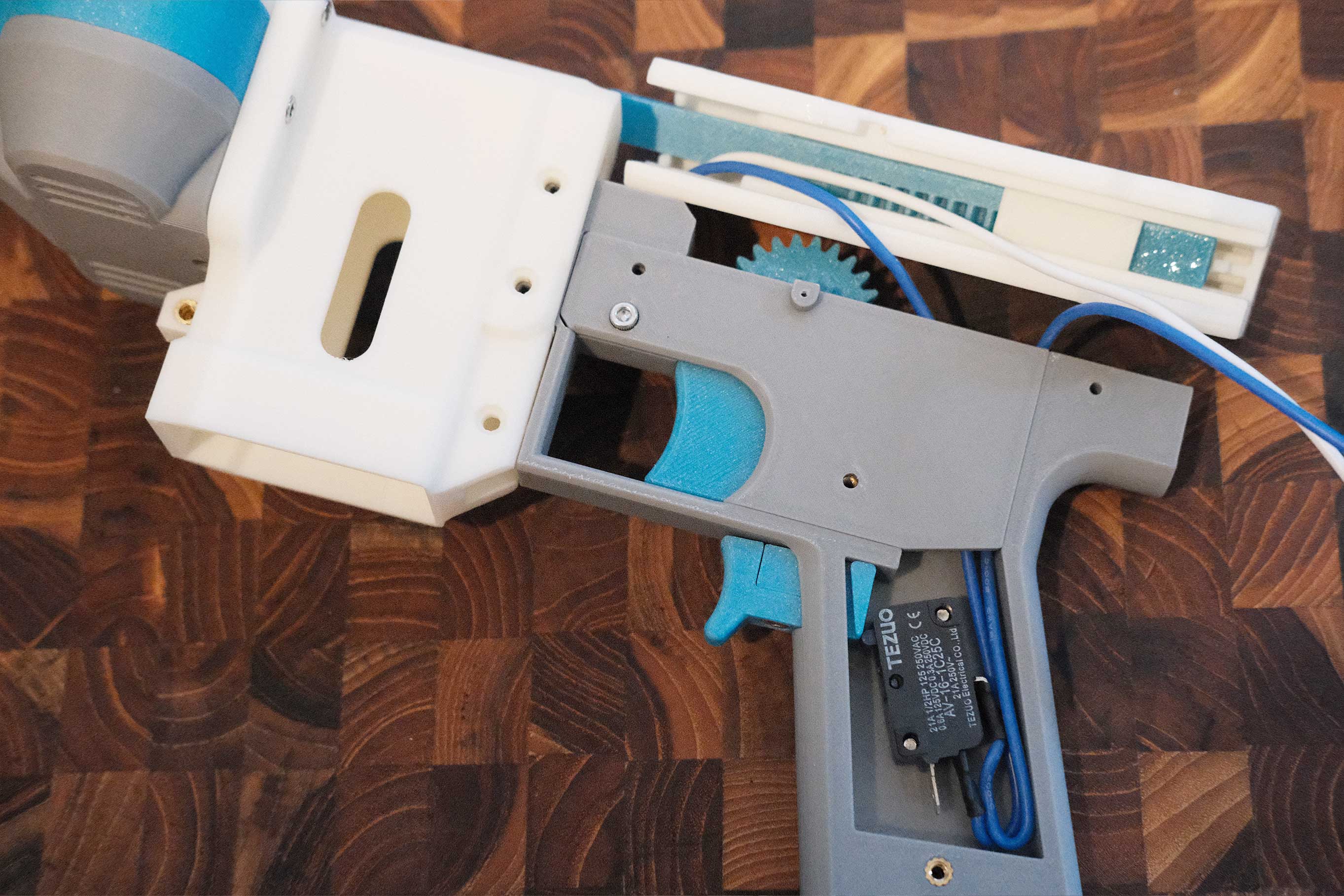

Grip with Switch Posts

Grip with Switch Posts

Install the two screws that form the switch seating posts.

- 2 x M3x10 SHCS

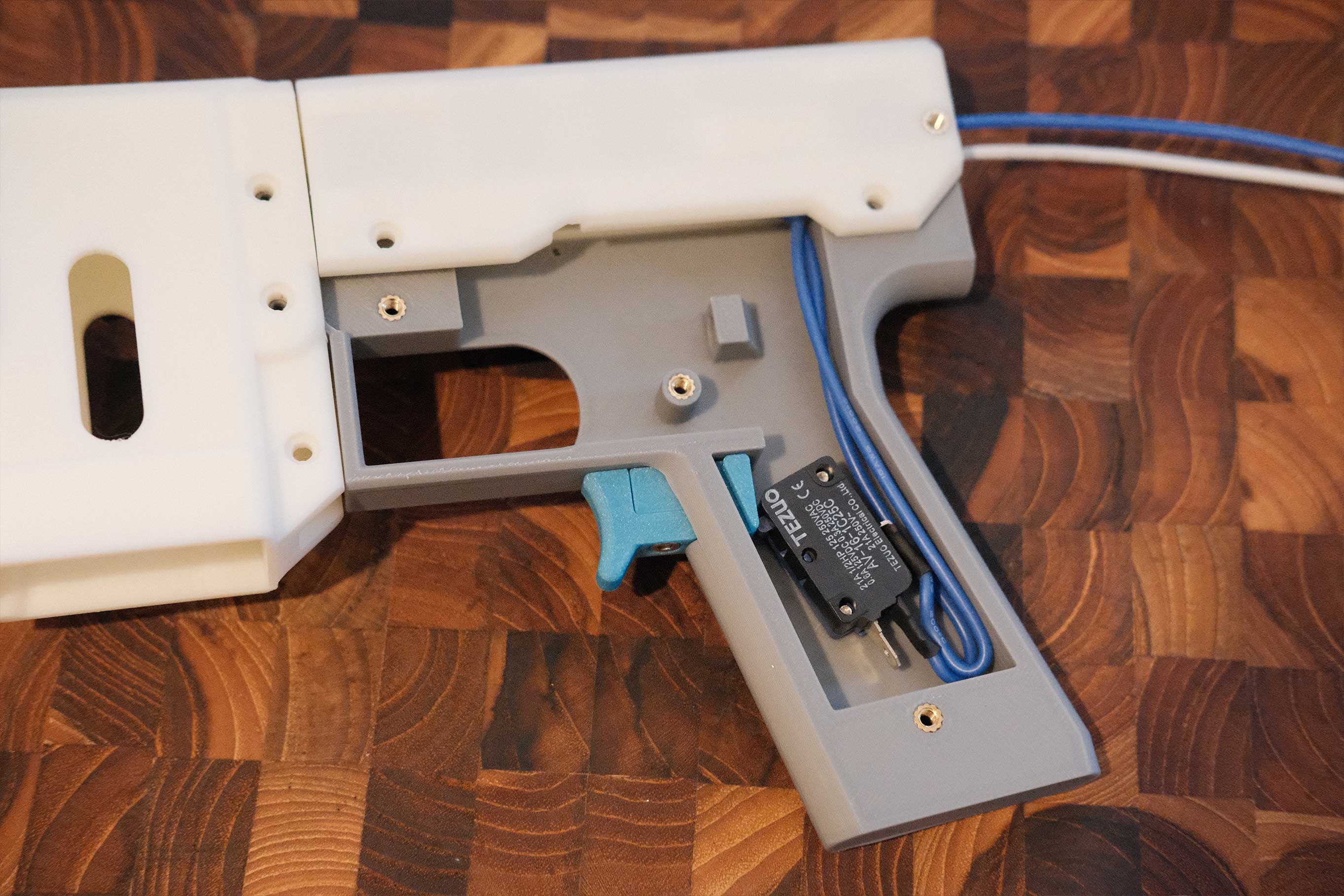

Switch Placement

Switch Placement

The 21A switch sits like so.

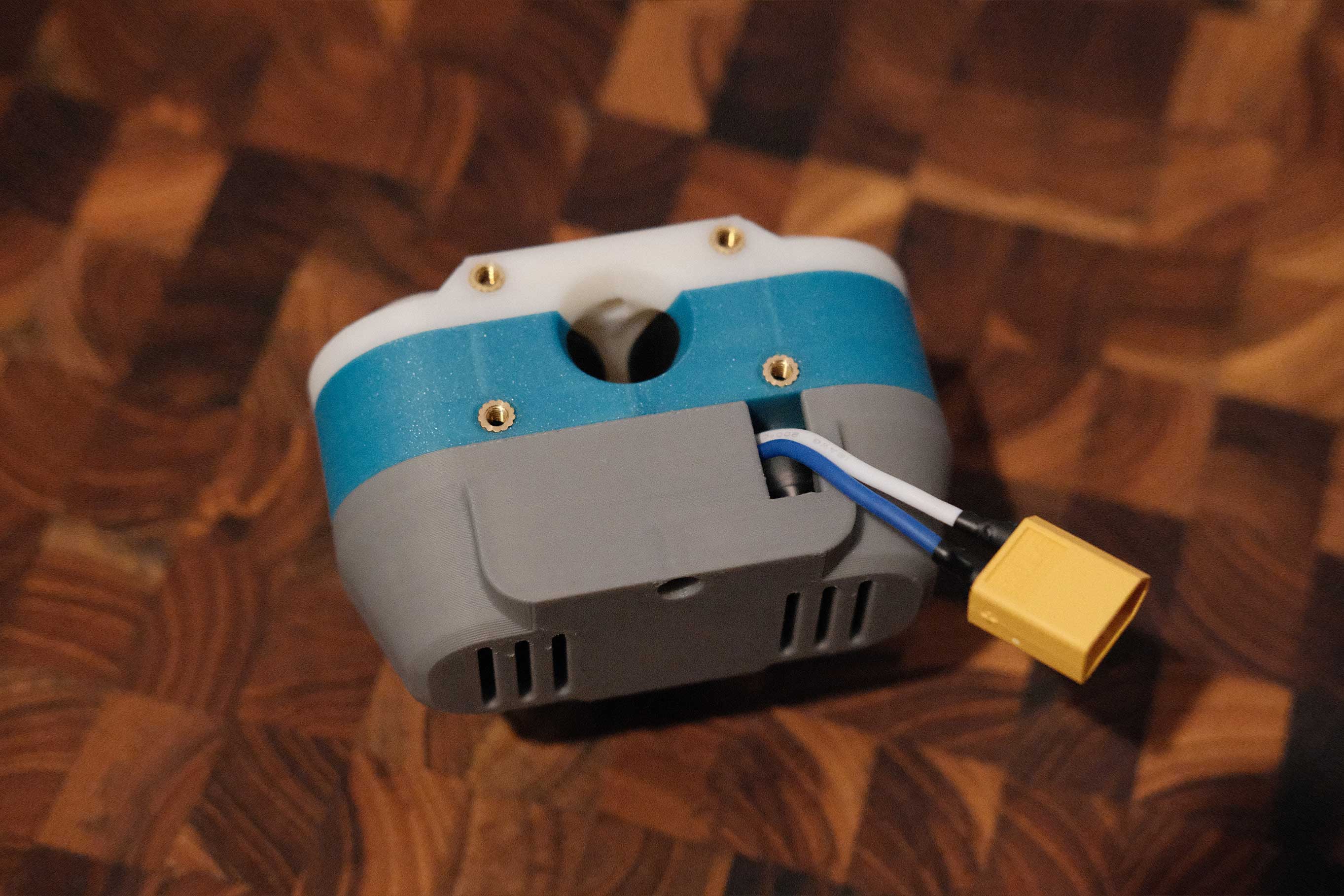

Required Wires

Required Wires

Positive wire (blue) has two runs; one from the motors to the switch, and one from the switch to the battery. We’ll be using NO and COM terminals to power the motors only when the trigger is pressed. Negative wire (white) goes directly from the motors to the battery.

Finish the Motors’ XT60 Connector

Finish the Motors’ XT60 Connector

Solder the wires to the XT60 male connector, connect it to the motors, then feed the wires through the top cover.

Solder the 21A Switch

Solder the 21A Switch

Solder the other end of the motors-to-switch positive wire and one end of the switch-to-battery wire to the NO and COM terminals of the switch. It does not matter which wire goes to NO and COM.

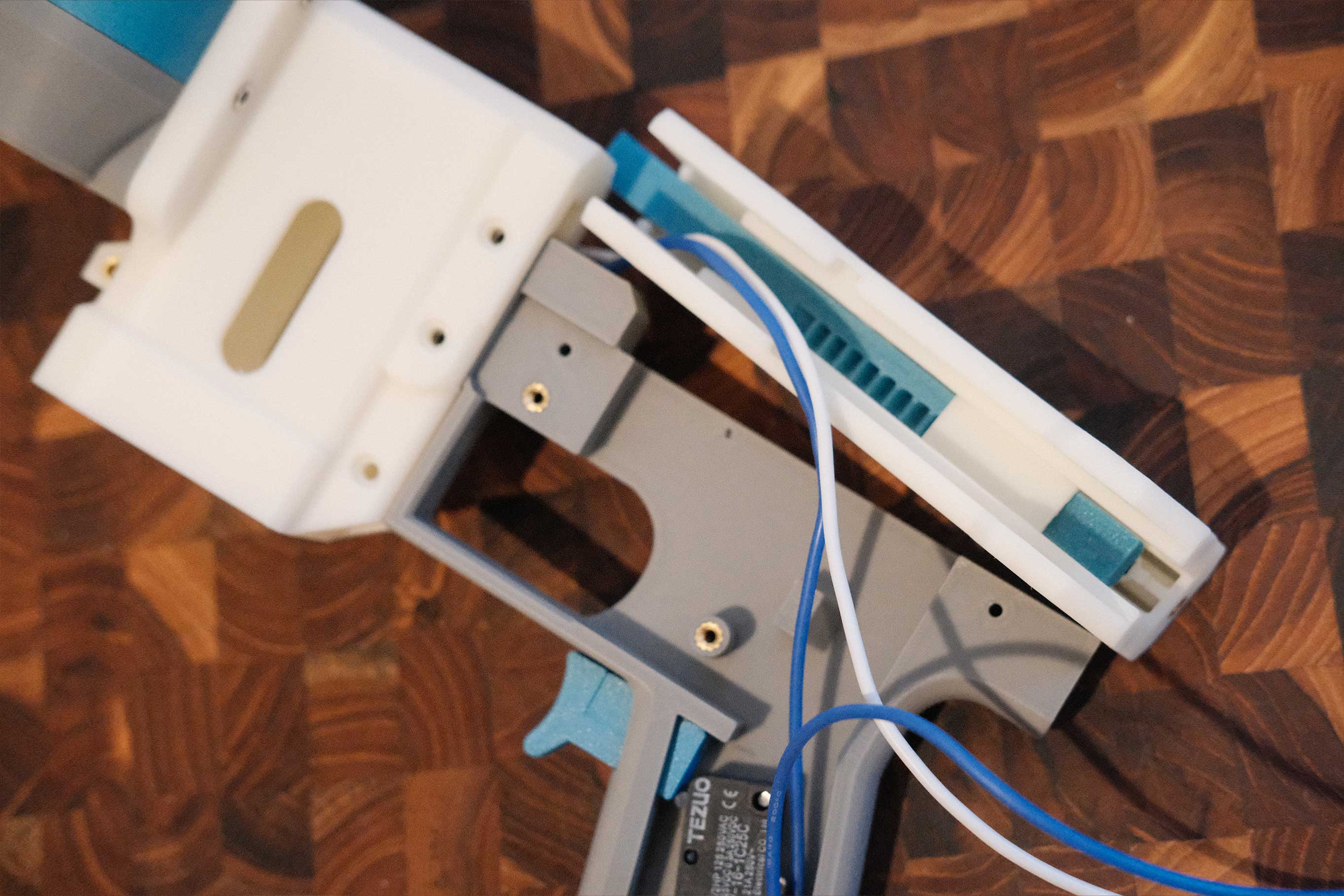

Install Switch Trigger and Tuck Wires

Install Switch Trigger and Tuck Wires

Assemble and install the switch trigger. Apply a bit of silicone grease to smoothen the action. Wires will tuck like so.

- 1 x M3x6 SHCS

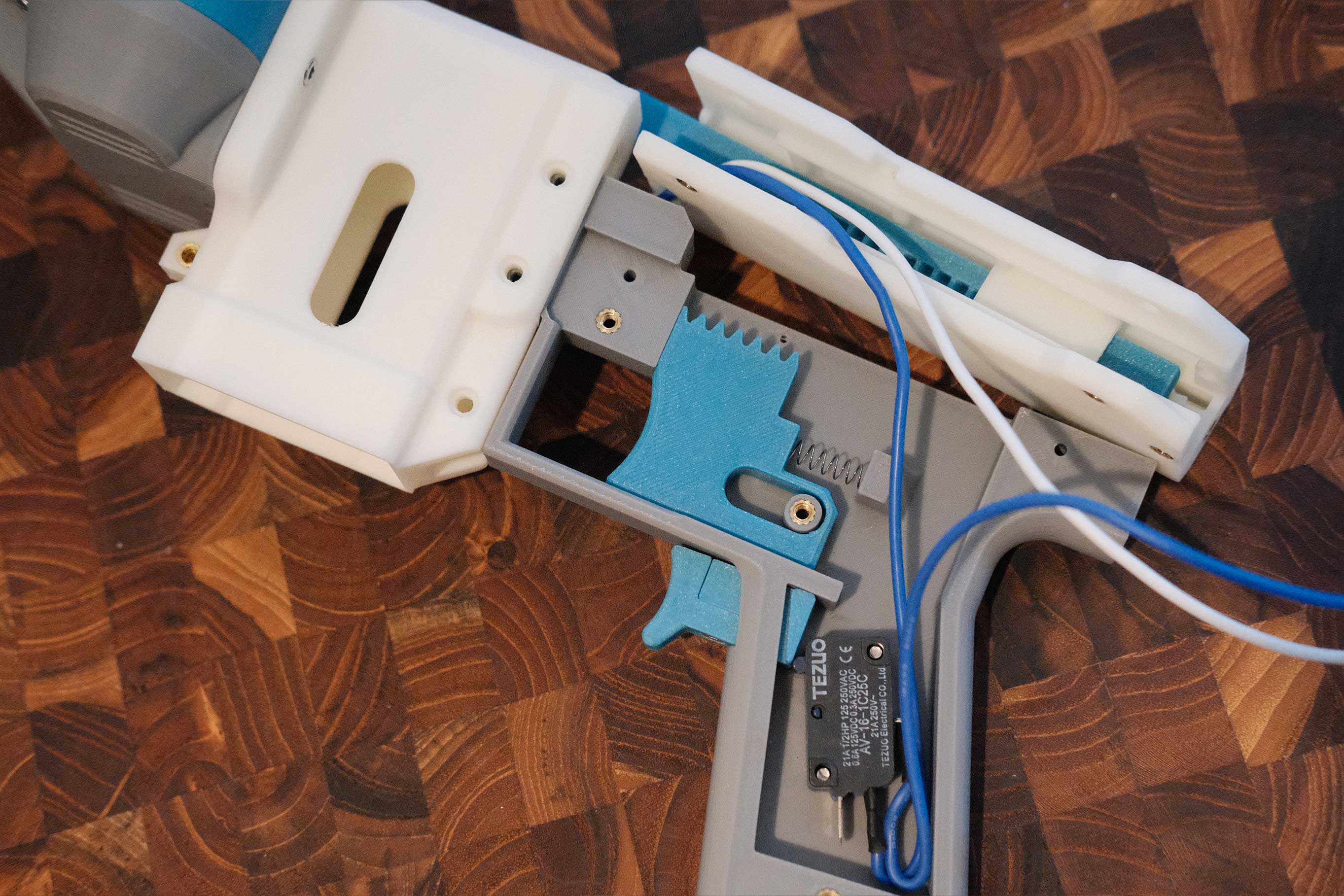

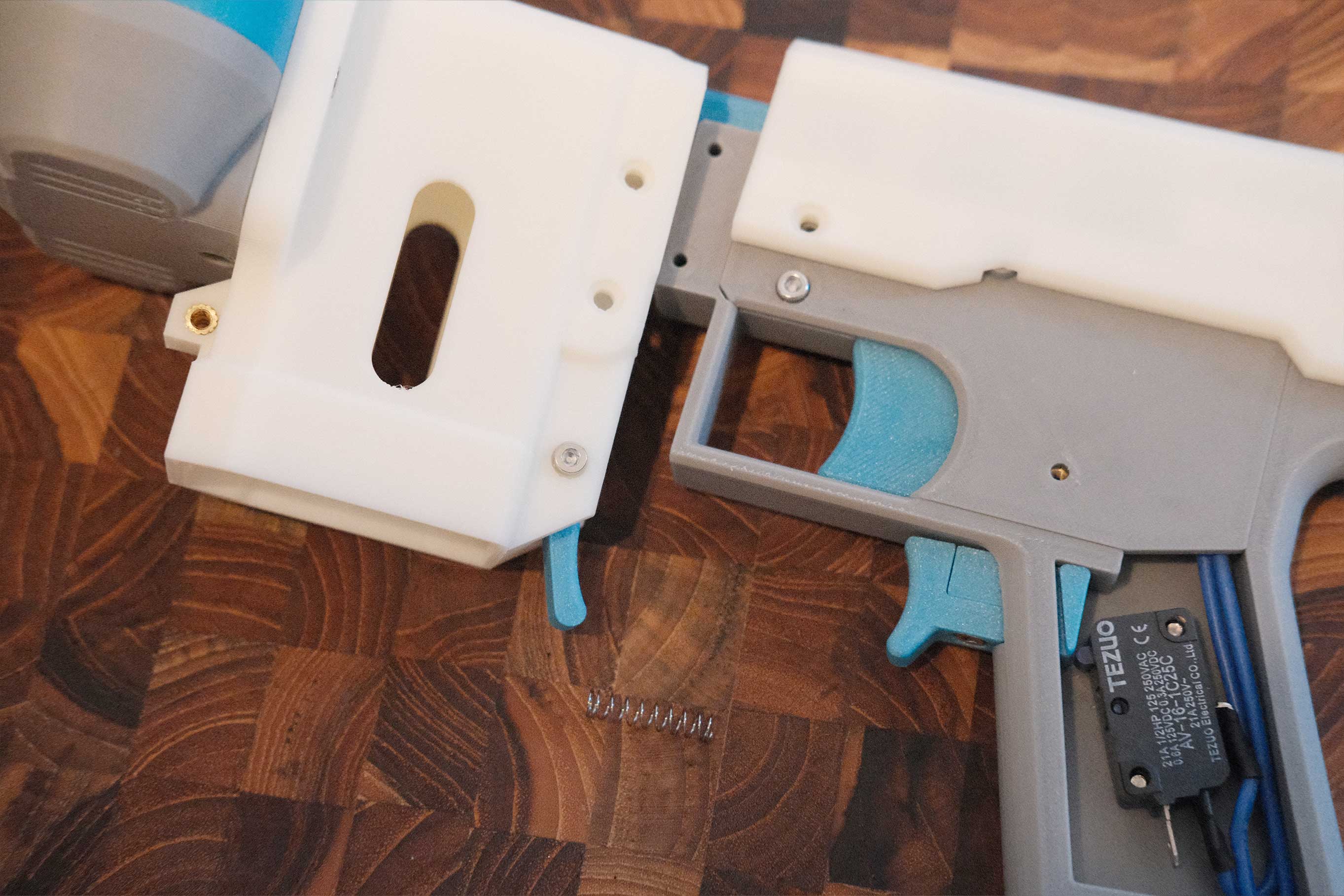

Install the Pusher

Install the Pusher

Install the pusher with the teeth on the far side and closer to the rear of the grip. Apply a bit of silicone to the sides of the pusher to smoothen the action.

Install the Trigger

Install the Trigger

Install the trigger with the spring. Depending on print quality and spring strength, you may need a second spring to ensure that the trigger and pusher returns to the original positions. Apply a bit of silicone grease to area around the post and spring to smoothen the action.

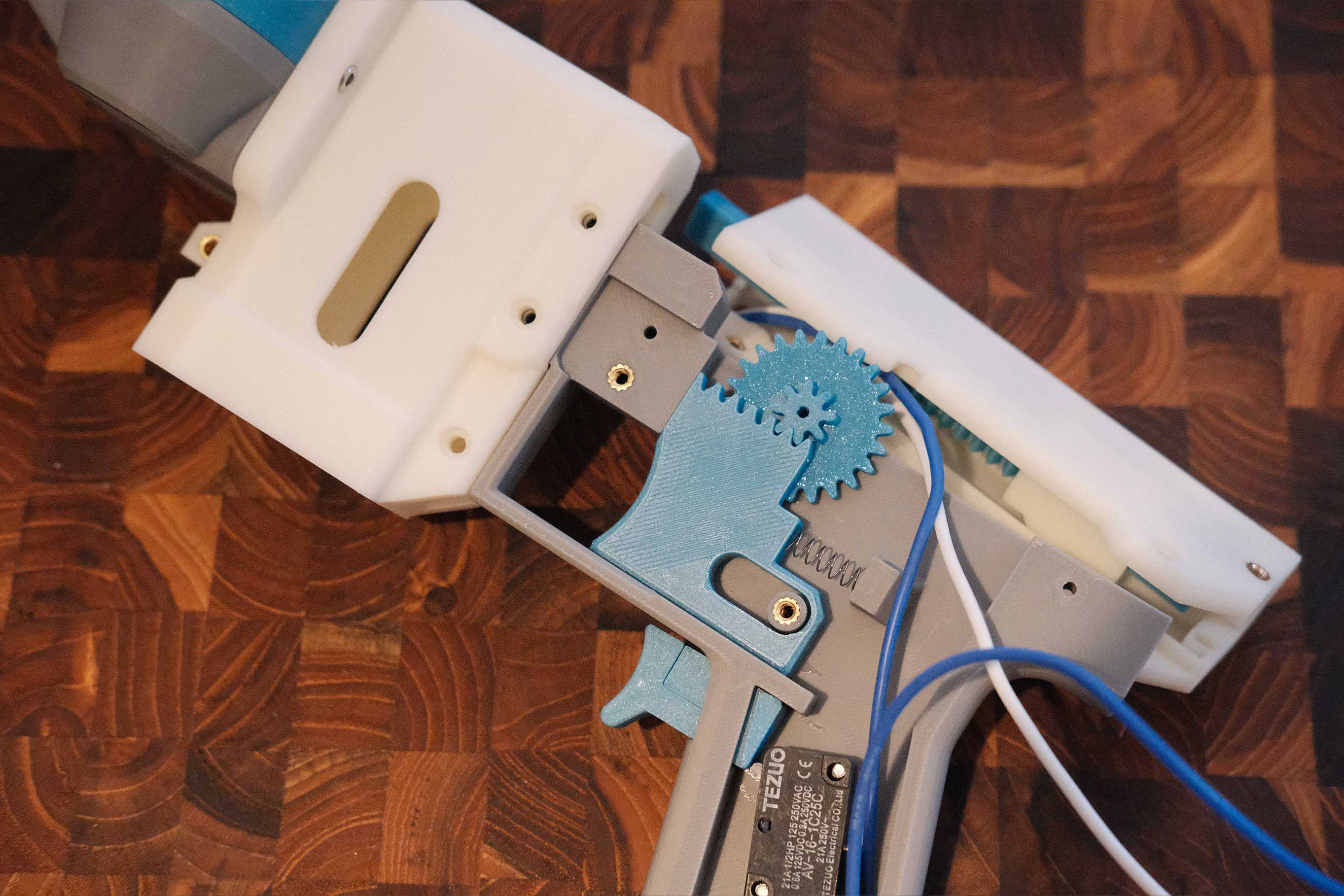

Install the Toothed Gear

Install the Toothed Gear

Install the toothed gear and line up the center hole with the receiving hole in the grip. Apply a bit of silicone grease to the faces of the gear to smoothen the action.

Install Grip Cover and Toothed Gear Shaft

Install Grip Cover and Toothed Gear Shaft

Secure the grip cover with an M3 screw, and insert the 2mm shaft through the cover, toothed gear, and grip frame.

- 1 x M3x6 SHCS

Close Top Cover

Close Top Cover

Close up the top cover. This part is fiddly. Wires should stay tucked behind the toothed gear and not impede the gear rotation. There’s a notch in the cover to accommodate the shaft.

Secure Mag Release

Secure Mag Release

Secure the mag release switch with an M3 screw.

- 1 x M3x16 SHCS

Install Spring and Connect Magwell with Grip

Install Spring and Connect Magwell with Grip

Place the mag release spring between the magrelease switch and grip frame, and insert the grip into the magwell. This is a good opportunity to test the trigger action. The trigger and pusher should extend and return with no sticking. Watching the action from the bottom of the magwell, you should see the pusher extend forward and retract all the way. If the pusher does not retract fully, it will prevent darts from feeding properly.

Install Magwell Wire Cover

Install Magwell Wire Cover

Install the wire cover over the XT60 connector.

- 2 x M3x6 SHCS

Install Right Scale

Install Right Scale

Install the right scale.

- 2 x M3x6 SHCS

Install Left Scale

Install Left Scale

Install the left scale.

- 2 x M3x6 SHCS

Install Remaining Screws

Install Remaining Screws

Secure the magwell, grip, and top cover with through screws.

- 4 x M3x25 SHCS

Stock

Check Wire Length

Check Wire Length

The wires need to feed through the buffer tube with a extra few inches to make it easy to handle the battery.

Finish XT60 Connector

Finish XT60 Connector

Add heatshrink and solder the wires to an XT60 female connector.

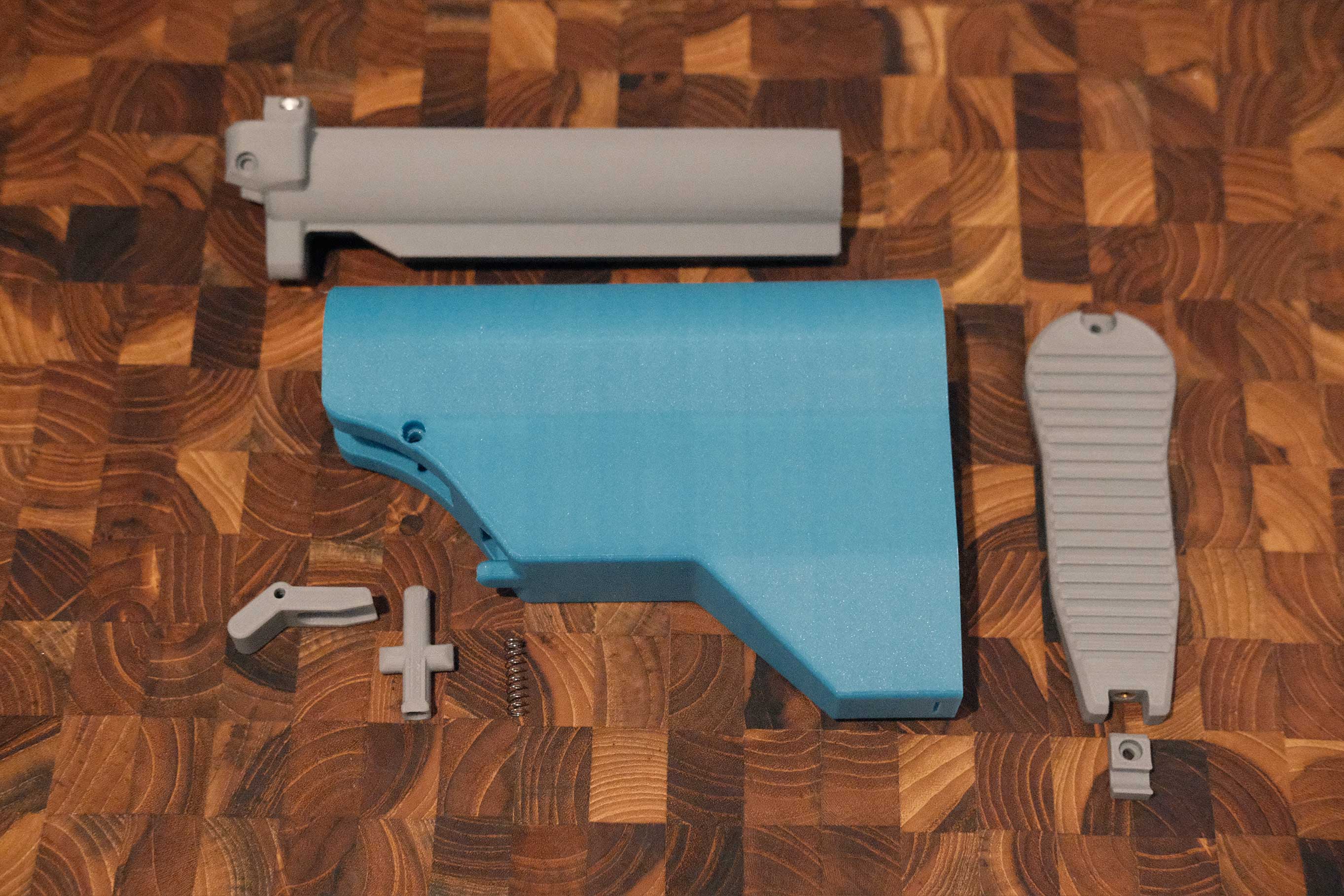

Stock Parts

Stock Parts

Sling Mount and Buttplate Hook

Sling Mount and Buttplate Hook

Attach the sling mount to the top of the buffer tube (my printed part has no sling mount), and install the buttplate hook.

- 2 x M3x12 SHCS

- 1 x M3x8 SHCS

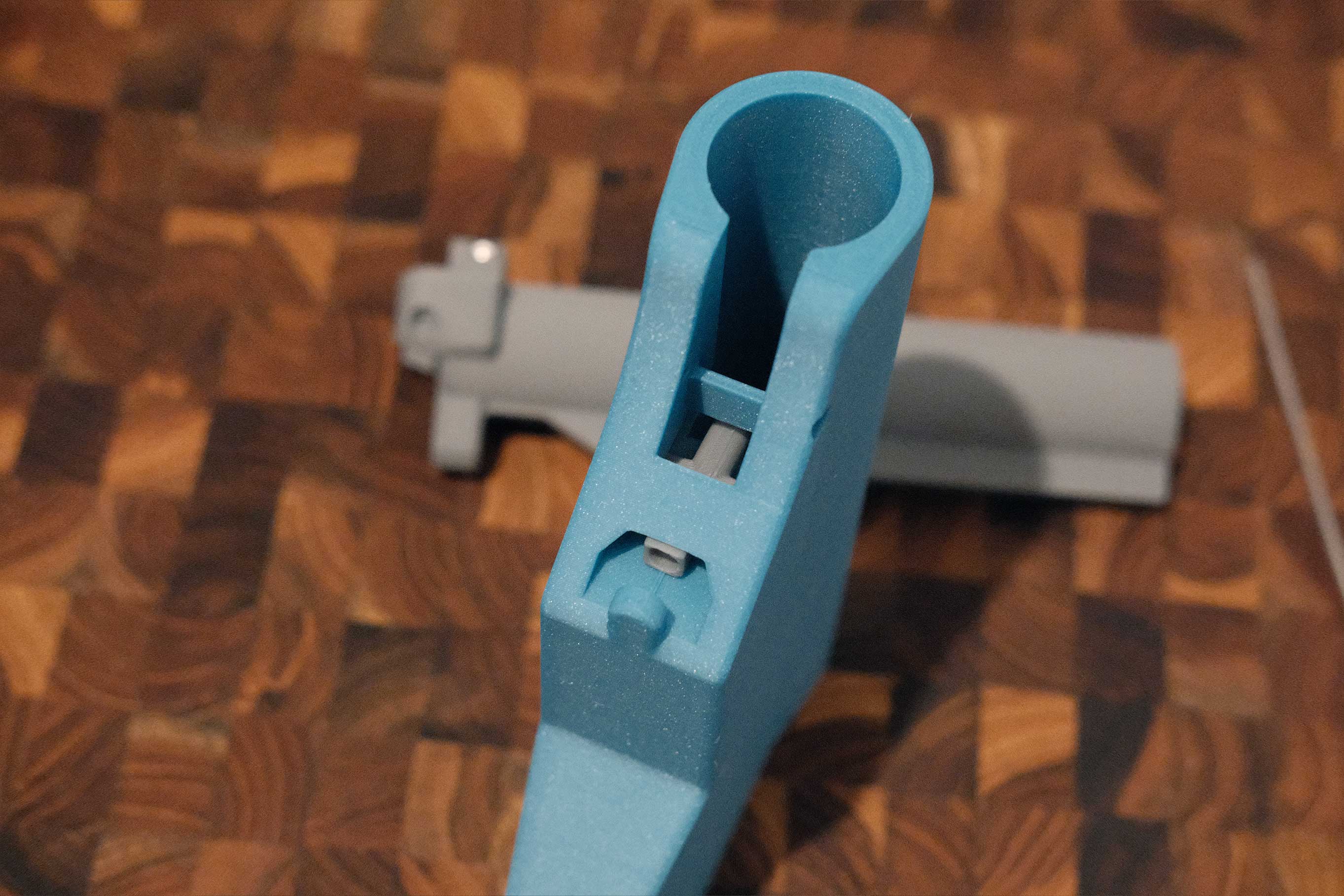

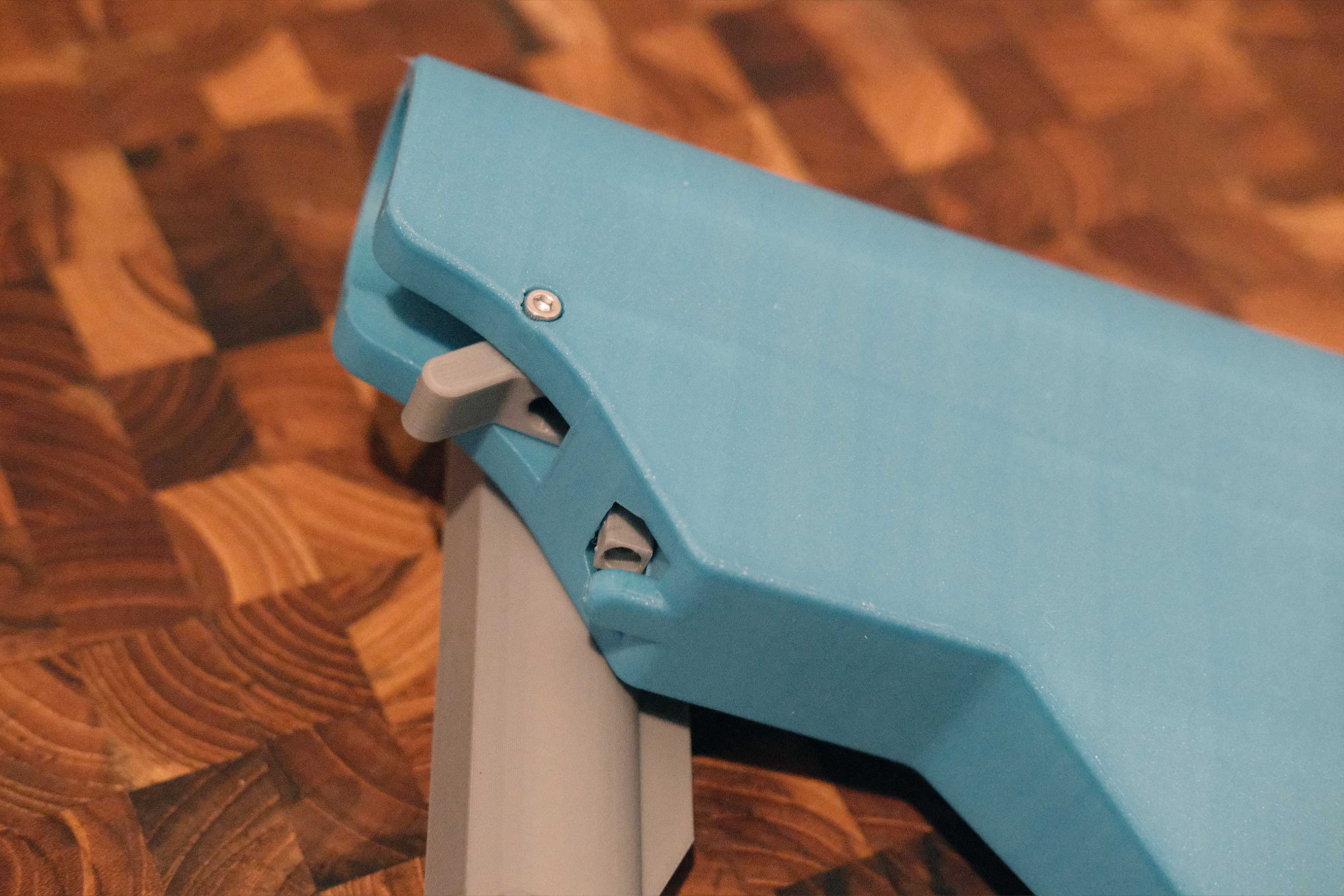

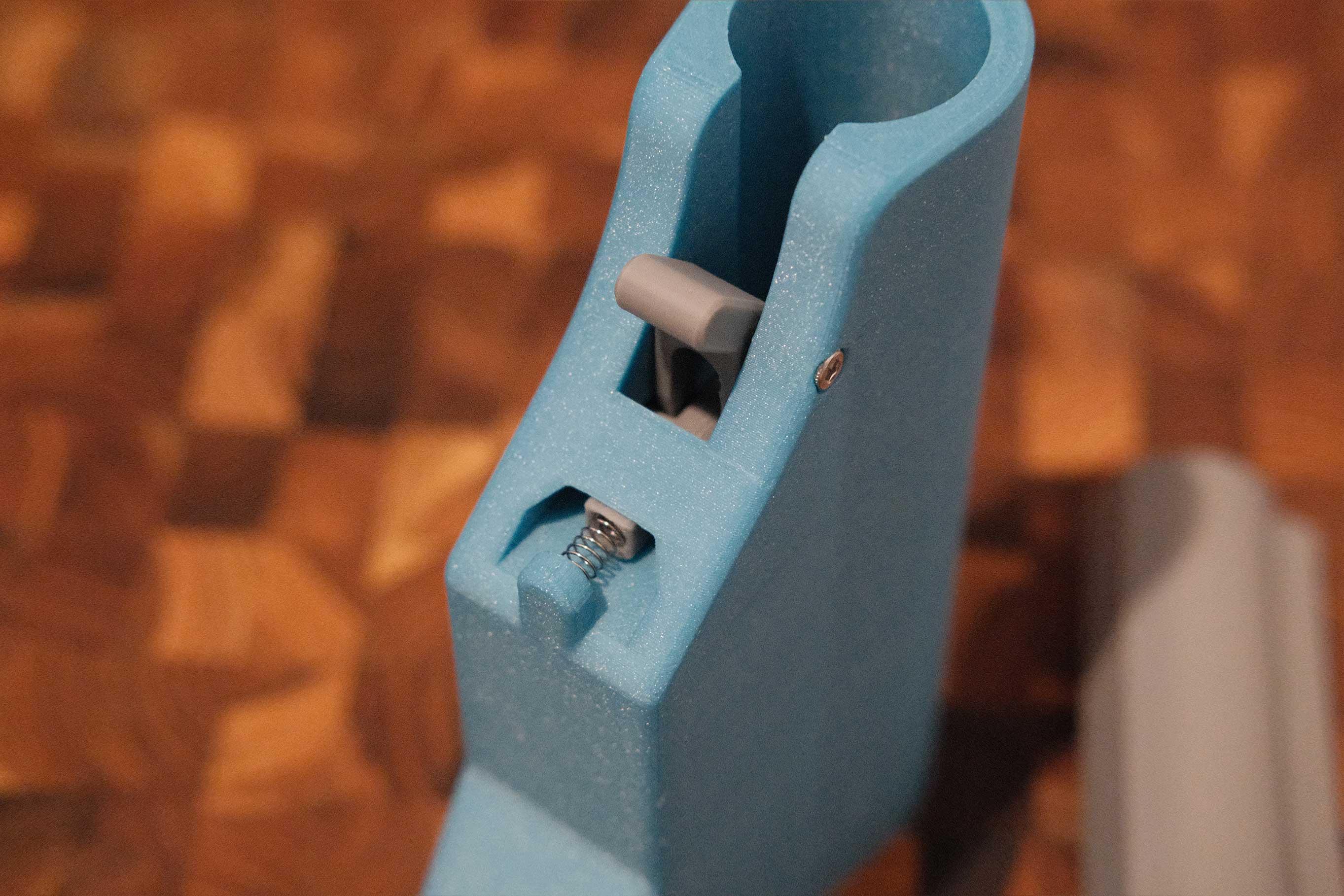

Insert Locking Pin

Insert Locking Pin

Insert the locking pin into the stock.

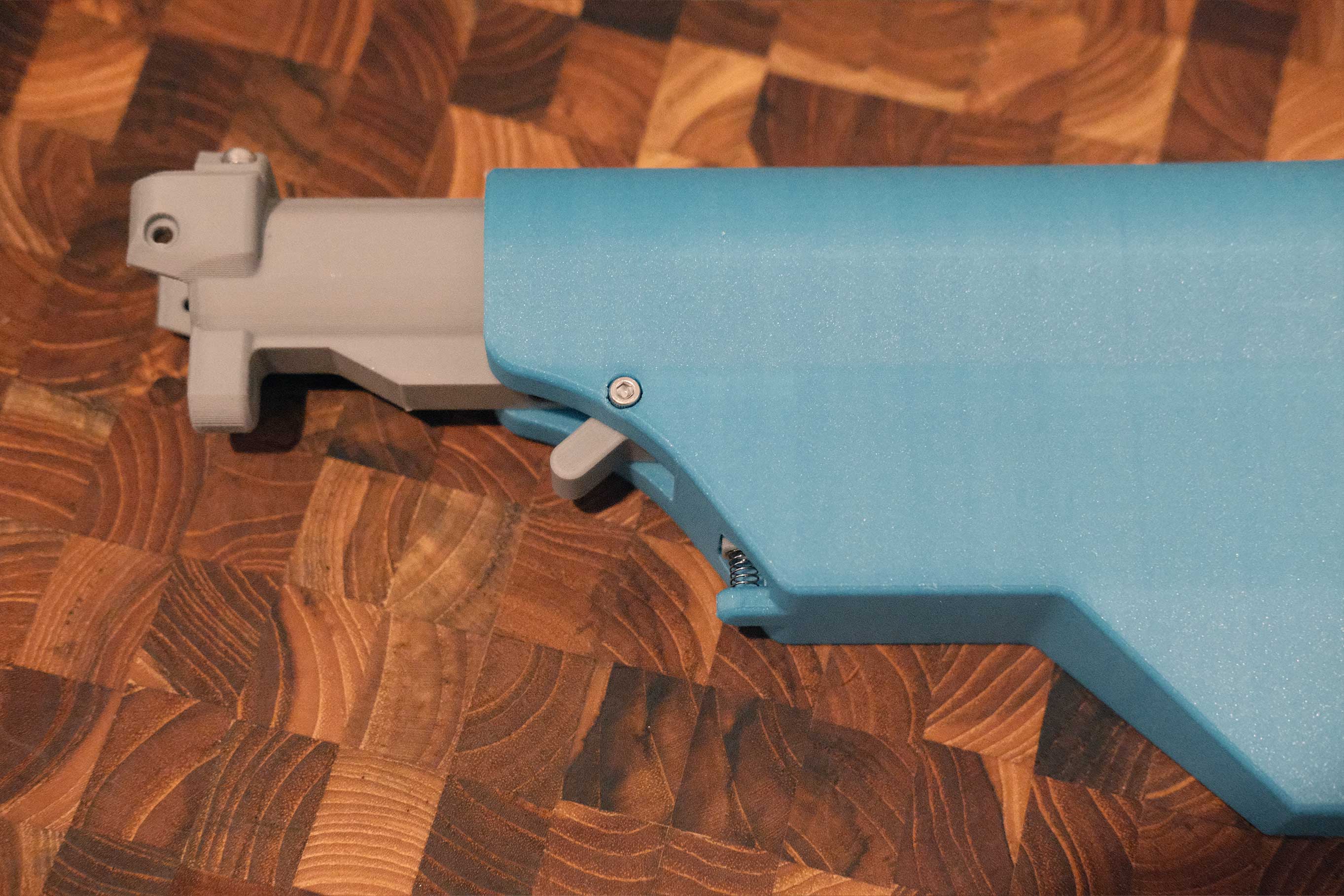

Secure Lock Release

Secure Lock Release

Install the lock release.

- 1 x M3x20 SHCS

Add Spring

Add Spring

Add the spring. This spring needs to be strong enough to keep tension on the locking pin and prevent the stock from collapsing during use.

Insert Buffer Tube

Insert Buffer Tube

Insert the buffer tube.

Feed XT60 Connector

Feed XT60 Connector

Feed the XT60 connector through the buffer tube. It should stick out just a bit.

Attach Stock to Grip

Attach Stock to Grip

Attach the stock to the grip. There’s a screw on each side and two on the rear.

- 2 x M3x8 SHCS

- 2 x M3x12 SHCS

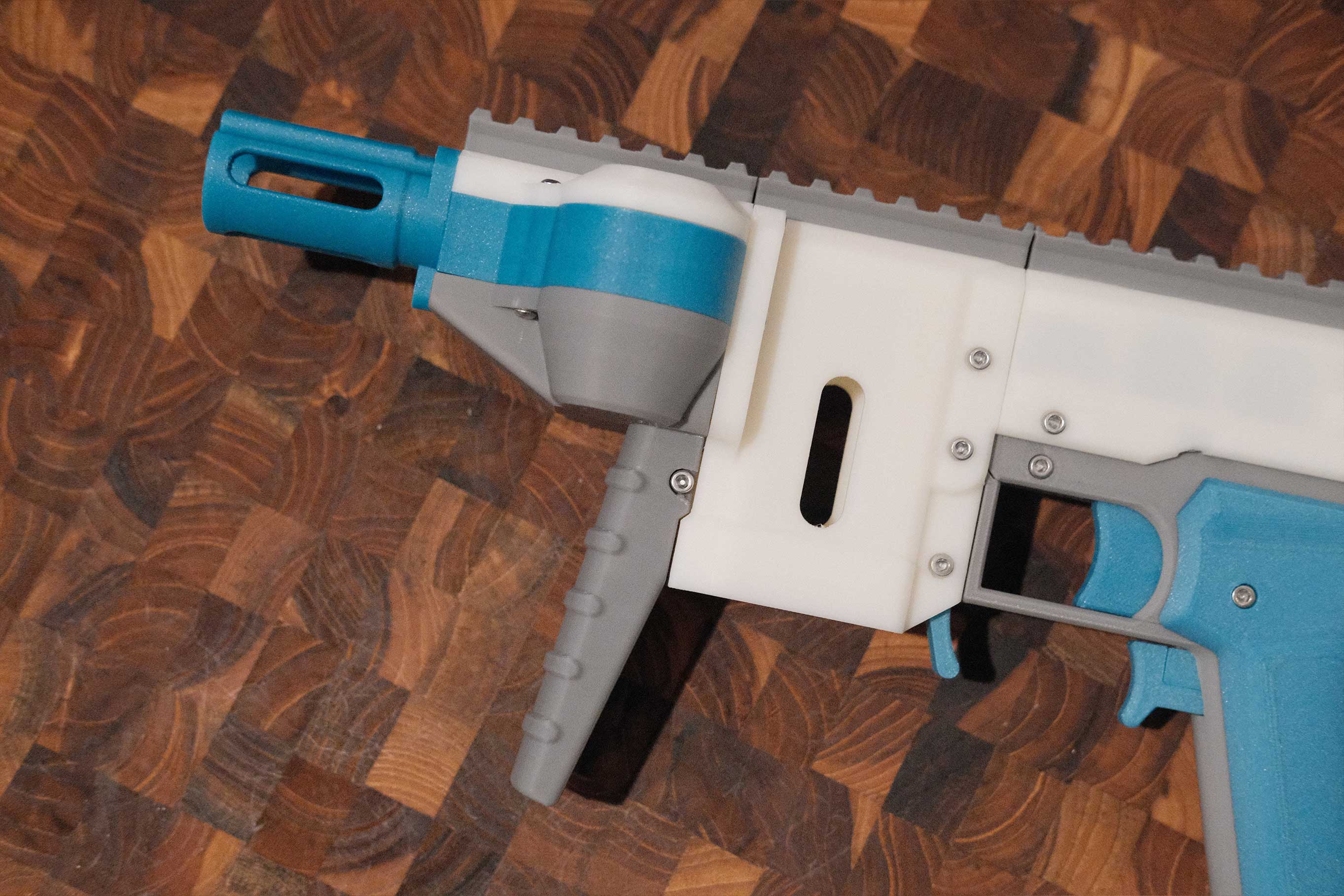

Flash Hider and Picatinny Rails

Flash Hider and Picatinny Rails

Attach the flash hider and picatinny rails.

- 9 x M3x8 SHCS

Flash Hider and Picatinny Rails

Flash Hider and Picatinny Rails

Should look like this.

Check Picatinny Spacing

Check Picatinny Spacing

Double check the picatinny pattern spacing.

Install Front Grip

Install Front Grip

Install your front grip of choice.

- 2 x M3x8 SHCS

Complete

Complete

Your Gryphon/Gryphle0n is complete!